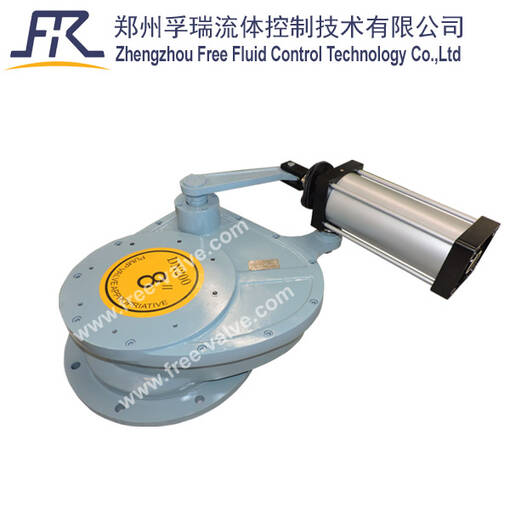

A heavy-duty double-plate gate valve engineered for dry powder handling systems such as power-plant ash transport, cement powder conveying and mineral-dressing processes. The valve uses structural (toughened) ceramic sealing faces for high wear resistance where abrasive dry powders (e.g., fly ash) contact the closure surfaces, extending service life in frequent open/close cycles.

Key benefits

- Ceramic sealing pair with high wear resistance for abrasive powders, reducing maintenance and downtime.

- Double-disc design with an interposed spring provides bidirectional, low-pressure self-sealing through flexible preload, preventing leak paths and reducing dust ingress.

- Disc rotational movement during operation minimizes ash deposition on the sealing surfaces, preserving tight sealing over repeated cycles.

- Configurable blow-sweep port or automatic blow-sweep device options help clear accumulated material from the valve body when required.

- Available for pneumatic actuation or manual operation to suit plant integration and control strategies.

Technical highlights

- Size range: NPS4–NPS12 (DN100–DN300)

- Pressure ratings: Class 150 / PN6 / PN10

- Temperature range: 0 to 200 °C

- Connection type: Flanged (ASME flange standards)

- Sealing material: Engineering/structural ceramics

- Pressure and leakage testing: GB/T13927, API 598

- Face-to-face dimensions: GB/T12221, API 609

- Operating modes: Pneumatic or manual

Typical applications

- Power plant ash handling and fly-ash conveying

- Cement industry dry-powder pipelines and feeders

- Mineral dressing and dry powder selection or transfer systems

Ordering & commercial information

- Typical price range: USD 500–5,000 per set (depends on size, materials, actuation and options)

- Common commercial terms: FOB, CIF, CFR, FCA

- Typical payment terms: TT, LC

- Typical lead time: ~30 days (subject to order quantity and configuration)

Model reference: FRZ644TC

If you require performance curves, material certificates, dimensional drawings or guidance on selecting actuators and blow-sweep options for specific process conditions (particle size, bulk density, operating pressure and temperature), provide those parameters so a tailored recommendation can be prepared.