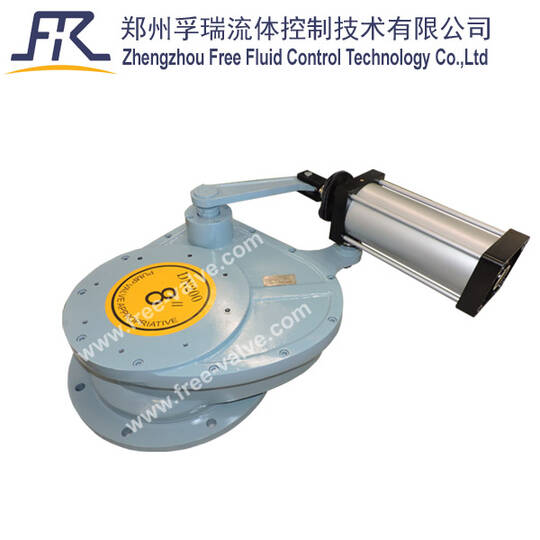

Compact pneumatic swing ceramic feed valve engineered for pressurized and vacuum pneumatic-conveying systems and discharge/vent applications where abrasive, fine particulate (fly ash, cement dust, cereal grains, etc.) must be reliably isolated or metered.

Key features

- Ceramic-to-ceramic sealing faces: fully toughened engineering ceramic seats and discs that are precision ground and polished for long-lasting abrasion resistance and reliable sealing under erosive service.

- Pneumatic actuation: cylinder piston rod is isolated from the conveyed medium to extend cylinder life and allow higher service temperatures without media contact damage.

- Swing/disc design: rotational motion of the disc reduces ash build-up on sealing surfaces, improving opening/closing reliability and service intervals.

- Floating spring-loaded disc: a floating spring between disc and seat maintains consistent contact force to ensure tight sealing and compensates for thermal expansion/contraction.

- Slanted outlet geometry: valve body outlet is sloped so conveyed material falls away from the valve cavity, preventing accumulation that can inhibit operation.

- Customizable dimensions: available in configurable face-to-face lengths and connection sizes to suit line layouts.

Technical specifications

- Size range: NPS 4–12 (DN100–DN300)

- Pressure classes: Class 150 / PN6 / PN10

- Temperature range: 0 to 200 °C

- Connection: flange

- Sealing material: engineering ceramic

- Pressure testing: GB/T13927, API 598

- Face-to-face standard: GB/T12221, API 609

- Valve body standard: GB/T12224, ASME

- Operating mode: pneumatic

Typical applications

- Fly-ash handling and isolation valves in coal-fired power plants

- Pneumatic conveying systems for cement, bulk cereals, and other powders

- Discharge and venting duties in steel plants and industrial dust-handling systems

- Any pressurized or vacuum conveying line requiring abrasion-resistant, tight-sealing valves

Benefits

- Significantly extended sealing life in abrasive services compared with metal-seat valves

- Reduced downtime and maintenance due to minimized deposit formation and isolated actuator components

- Reliable tight shutoff across thermal cycles owing to floating spring compensation

- Suitable for integration into existing flanged piping and standard pneumatic actuation systems

Model and commercial notes

- Model: FRZ643TC

- Typical supply options include flange connections and customizable face-to-face lengths; standard pressure/face-to-face testing is performed per the listed standards.

- Indicative lead time and commercial terms are typically agreed per order (lead times and pricing vary by quantity and configuration).

Product Details

Harmonized commodity

Brand:

FREE-VALVE

Country of origin:

China

Industrial sector:

MPN:

FRZ643TC

Model:

FRZ643TC

Unit type:

Piece