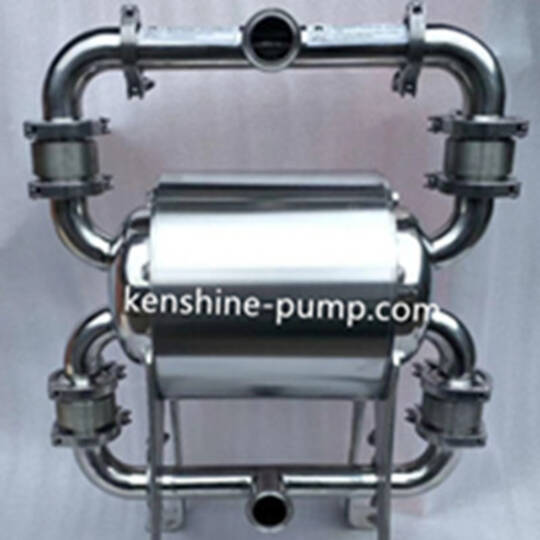

A sanitary, air‑driven diaphragm pump engineered for food, beverage, pharmaceutical and other hygienic processing environments. The pump is a seal‑less, explosion‑proof pneumatic diaphragm design that delivers low‑shear, self‑priming operation with simple maintenance and light weight for easy installation and service.

Key features and benefits

- Hygienic wetted parts in stainless steel (SS304 / SS316 / SS316L) manufactured to food‑grade standards

- Precision cast pump body with smooth surface finish and improved strength for sanitary applications

- High‑roundness valve balls with tight sealing for reliable one‑way operation and consistent discharge

- Diaphragm travel optimized to reduce stress and extend diaphragm life

- Four‑bolt fluid chamber connection for robust sealing; actual dry suction capability up to 0–4 m

- Three‑section upper and lower cover for flexible installation and access

- Integrated diaphragm retaining block with high temperature and pressure resistance

- Wear‑resistant stainless steel diaphragm connecting rod for improved corrosion resistance and longer service life

- Air distribution valve with three‑way pilot (no O‑rings/cylindrical valve) to reduce dead points, eliminate stoppage and provide stable, low‑pulse flow

Operation summary

Two flexible diaphragms are linked by a connecting rod and driven by alternating compressed air in the valve chamber. Each side contains two one‑way ball valves; diaphragm reciprocation changes chamber volume so the valves open and close alternately, producing continuous suction and discharge. The air distribution system provides reliable switching of the diaphragms for smooth, synchronized operation and reduced pulsation.

Typical applications

Food and beverage processing, breweries/distilleries, dairy and liquid foods, pharmaceutical and personal care manufacture, chemical and daily‑use products where sanitary construction, low shear and easy maintenance are required.

Ordering options

Available with wetted components in SS304, SS316 or SS316L. Contact your supplier for model sizing, flow rates and compatibility with specific process fluids.