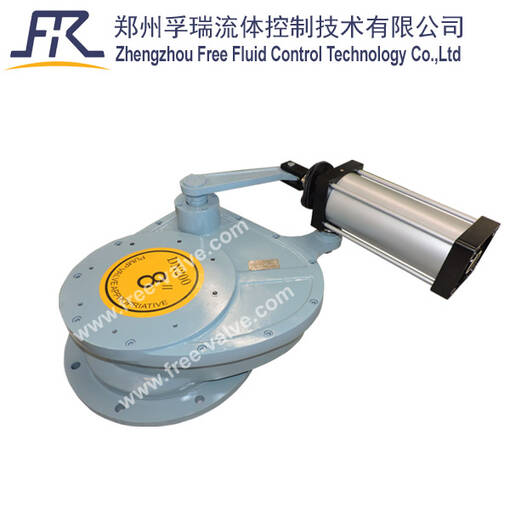

Pneumatic ceramic double-disc gate valve designed for handling and feeding dry powders in transport pipelines. The valve uses engineering (toughened) ceramic sealing surfaces and a double-disc layout to deliver high wear resistance and reliable bi-directional sealing in frequent open/close duty. A spring inserted between the two valve discs provides a flexible preload for self-sealing at low differential pressures, and the valve disc auto-rotates to reduce localized wear and prevent dust clogging.

Key features

- Sealing surfaces: structural/engineering ceramic for high abrasion resistance

- Double-disc design: enables two-sided (bi-directional) sealing

- Spring preload between discs: ensures self-sealing and reduces dust ingress during cycling

- Auto-rotating valve discs: spreads wear across the sealing surface for longer life

- Suitable for frequent open/close operation with stable sealing performance and low maintenance

Typical specifications

- Size range: DN50–DN300 (NPS 2–12)

- Connection type: flange (flange standards per ASME)

- Maximum working temperature: ≤ 200 °C

- Actuation: pneumatic (primary) and manual options available

- Sealing material: engineering ceramic

- Pressure and face-to-face tests/standards: GB/T13927, API598; face-to-face per GB/T12221, API609

Applications

Engineered for dry, abrasive bulk powder handling such as cement and similar industries where high abrasion resistance, tight sealing and frequent cycling are required. Well suited for on/off isolation in powder conveying lines, feeders and dump systems.