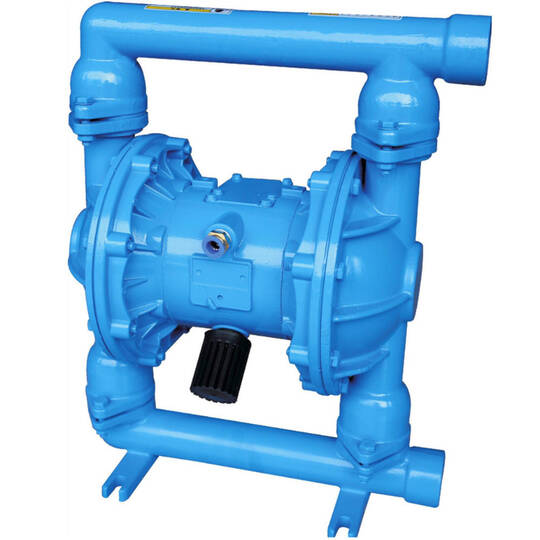

Air‑operated (pneumatic) double‑diaphragm (AODD) transfer pump engineered for reliable, low‑maintenance handling of liquids, slurries and aggressive media. Available wet‑end materials include cast iron, aluminum alloy, stainless steel, polypropylene (PP), PVDF and steel lined with FEP, allowing selection for chemical compatibility and abrasion resistance.

Key performance and features

- Self‑priming (suction lift up to 5 m) and capable of discharge heads up to 70 m; export/discharge pressure ≥ 6 kgf/cm².

- Pneumatic inlet pressure adjustable between 1–7 kgf/cm² to achieve stepless flow control.

- Handles solids and entrained particles up to 10 mm diameter; suitable for viscous fluids up to 10,000 cP.

- Diaphragm design eliminates rotary seals and shaft bearings; process fluid is fully isolated from moving parts to prevent leaks and environmental contamination.

- Air‑powered — no electricity required, making it safe for use in flammable or explosive atmospheres.

- Can be operated submerged in the medium when required.

- Dry‑run tolerant, requires no oil lubrication; pump will stop automatically on overload and restart when conditions normalize.

- Simple construction with few wear parts — easy access to diaphragms and valves for fast maintenance and reduced downtime.

Typical applications

- Chemical transfer and dosing

- Slurry and solids‑laden liquid handling (mining, mineral processing)

- Wastewater, dewatering and tank emptying

- Paints, inks, adhesives and coatings (viscous and shear‑sensitive fluids)

- Petrochemical, shipbuilding and industrial process transfer where leak containment and explosion safety are required

Why specify this AODD pump

Its robust materials options and diaphragm isolation make it a versatile choice for corrosive, abrasive or toxic fluids where leak prevention and safe operation are priorities. The absence of rotating seals simplifies maintenance and lowers lifecycle cost, while pneumatic control offers intrinsically safe operation and flexible flow control without electronic drives.