Heavy-duty Y-type slurry valve designed for handling abrasive, high-density slurries in demanding industrial environments (alumina, mining, metallurgy, chemical fertilizer, paper-making). The valve’s split-body (left/right) construction places a replaceable seat between the two halves so the seat can be exchanged quickly without replacing the entire body — reducing downtime and maintenance cost.

Key features

- Split (bi-part) body with bolted connection and centrally located, replaceable seat for fast maintenance and reduced spare-part inventory

- Flow-optimized cavity geometry developed with 3D design and finite element analysis to minimize turbulence and wear

- High-abrasion sealing options: full Stellite or tungsten-carbide overlay on the seat for superior hardness and extended service life

- Anti-wash and anti-corrosion stem protection plus anti-wash/anti-corrosion protection plates inside the body to protect internal components from erosive flow

- Rotation-resistant device ensuring the stem performs only straight-line motion (prevents stem twisting and seat damage)

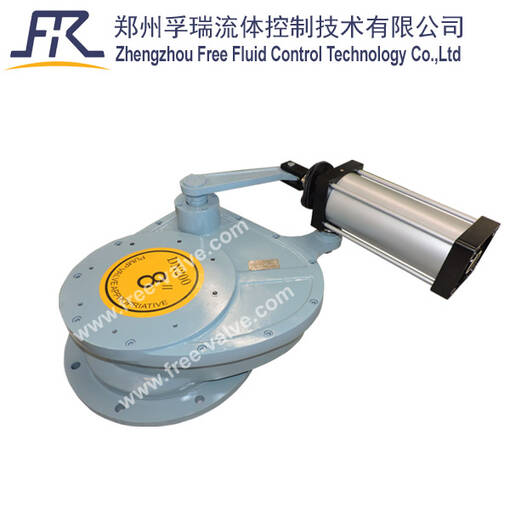

- Multiple actuation options: manual, pneumatic, or electric to suit process automation requirements

Standards & typical specifications

- Connection: Flanged (ASME)

- Design / face-to-face: conforms to ASME / GB/T12221 / API609 where applicable

- Pressure rating: Class 150 through Class 600

- Size range: DN50–DN500 (NPS 2–20)

- Materials: carbon steel or stainless steel bodies; alloy sealing surfaces

- Maximum service temperature: ≤ 425 °C (application dependent based on materials and sealing)

- Pressure testing: GB/T13927 or API598

Applications

Engineered for slurry service where abrasion, erosion and corrosion are concerns — commonly used in alumina plants, mining operations, metallurgical processes, chemical fertilizer plants and paper mills. Ideal for flow control or shut-off of abrasive slurries where robust sealing and easy maintenance are required.

Ordering note

Available in multiple materials, seat overlay options and actuation types; specify required pressure class, size (DN/NPS), body material and actuation method when ordering. Model reference: FRJ545Y.