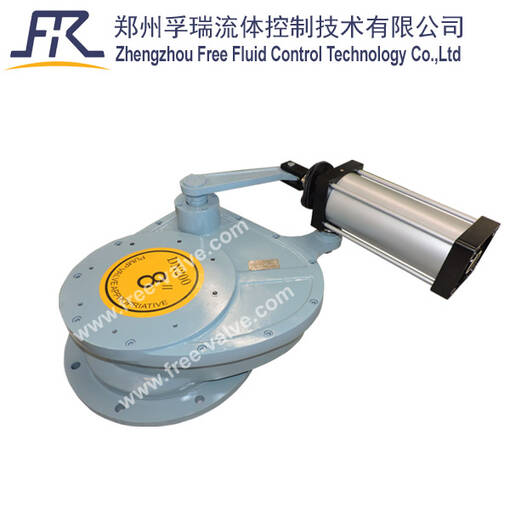

A wafer-type ceramic butterfly valve engineered for reliable control in highly abrasive and corrosive slurry services. The valve uses high-density ceramic facing on the disc, seat and sealing ring to deliver superior hardness and wear resistance compared with conventional stainless-steel trims, extending service life and reducing maintenance in demanding process environments.

Key features

- Wafer-style compact body for space-saving installation between flanges

- High-performance ceramic sealing and seating materials (high-purity alumina, zirconia, or solid tungsten carbide options) for excellent abrasion and cavitation resistance

- Disc and seat ceramics are dramatically harder than typical stainless steels, improving longevity in erosive slurries

- Body material options to suit process requirements: WCB, CF8, CF8M, CF3, CF3M

- Available actuation: manual (hand lever/gearbox) or pneumatic

- Adjustable throttling performance inherent to butterfly valve design

Technical specifications

- Model: FRD342TC

- Size range: DN100–DN300 (NPS 2–12)

- Pressure rating: PN6–PN25

- Temperature range: 0 to 200 °C

- Connection types: wafer or flanged

- Sealing material: engineering ceramics (99% alumina, zirconia, or tungsten carbide depending on application)

- Pressure and leakage testing standards: GB/T13927, API 598

- Face-to-face / dimensional standards: GB/T12221 and ASME-compatible options

- Valve body standards: GB/T12224 and ASME-compatible options

Typical applications

- Abrasive slurry handling: bauxite, mining slurries, coal wash effluent, ash slurry

- Bulk abrasive media: sand, quartz, grain handling where erosive wear is a concern

- Metallurgical dust or slurry services requiring corrosion and wear resistance

Commercial details (typical)

- Price range: USD 500–5,000 per set (depending on size, materials and options)

- Packaging/terms: FOB, CIF, FCA, CFR

- Payment terms: T/T, L/C

- Typical lead time: ~30 days (subject to order size and configuration)

Why choose ceramic-faced wafer butterfly valves

Ceramic-faced wafer butterfly valves combine the compact, low-torque advantages of wafer butterfly valves with the exceptional hardness and chemical resistance of engineered ceramics. For plants handling abrasive or erosive media, they significantly reduce downtime and lifecycle maintenance costs versus standard metal-trim valves.