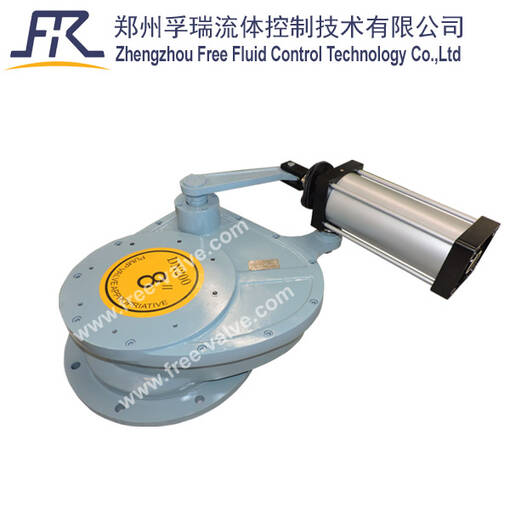

Wafer-style double-offset (double-eccentric) high-performance butterfly valve engineered for reliable shut-off and accurate throttling in demanding industrial services. The double-offset disc geometry minimizes seat contact during operation, delivering low operating torque, reduced wear and longer service life — ideal for frequent cycling and tight shut-off applications.

Key features

- Double-offset (double-eccentric) wafer design for low-torque operation and improved throttling control

- Available sealing options: resilient (soft) seats or metal-to-metal (hard) seats to match liquid, gas and slurry service requirements

- Replaceable seat ring secured with removable bolts for fast on-site maintenance and lower lifecycle cost

- Resilient-seated construction (when specified) to reduce seat wear and extend service life

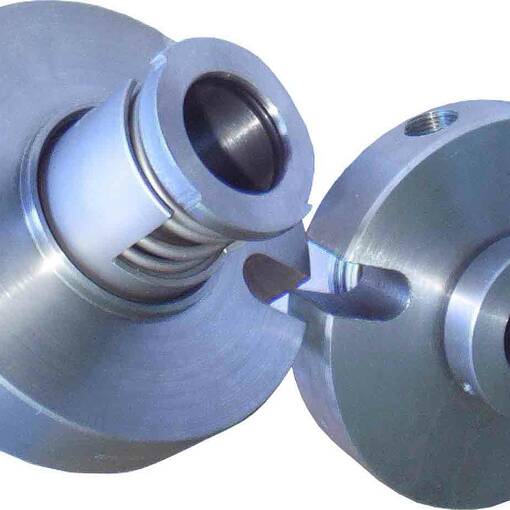

- Blowout-proof shaft design with self-lubricating components for safe, low-maintenance operation

- Mechanical travel stops to prevent over-travel and protect the disc and seat

- Sealing surface options: overlay or weld hard facings such as Stellite or tungsten carbide can be applied to the disc for enhanced abrasion and corrosion resistance

Technical overview

- Model: FRD342H

- Size range: NPS2–NPS48 (DN50 and above options available)

- Pressure ratings: Class 150–Class 300 (PN ratings available per request)

- Body materials: available in titanium grades (TA1, TA2, TA3, TA9, TA10, TC4) and other metallurgy options for corrosive environments

- Seat materials: PTFE (including filled PTFE), graphite-filled PTFE, or metal seat constructions

- Maximum working temperature: up to 250°C (selection depends on seat material and service conditions)

- End connection: wafer-style for between-flange installation (flange-compatible)

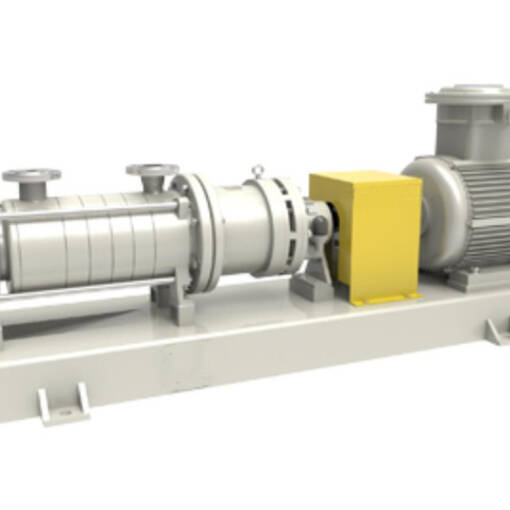

- Actuation options: manual worm gear, electric actuator, pneumatic actuator (custom actuation packages available)

- Testing & standards: pressure tested to GB/T 13927; face-to-face dimensions per GB/T 12221 (other standards available upon request)

Applications

Suited for chemical processing, petrochemical and refinery systems, natural gas, power plants, water and wastewater treatment, distribution networks and general industrial services where tight shut-off, durability and low-maintenance operation are required.

Ordering and options

Specify: model (FRD342H), size, pressure class, body and seat materials, disc facing/hardfacing (if required), and preferred actuation method. Optional surface treatments and testing/certification packages can be supplied to meet project specifications.