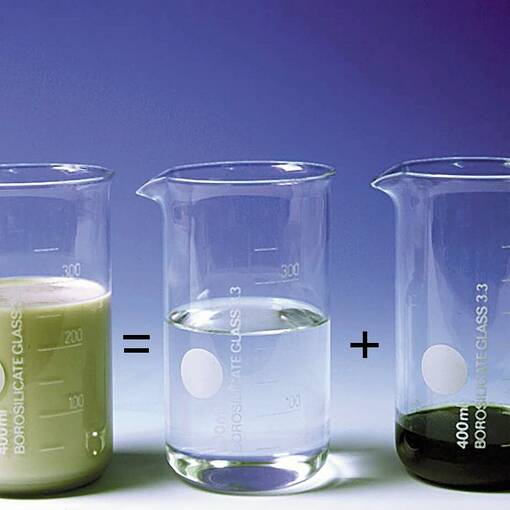

Robust, high-efficiency centrifugal pump engineered for reliable transport of solid–liquid two‑phase media such as paper pulp and slurry. Designed using modern two‑phase flow theory, this pump delivers improved throughput, longer service life and simplified maintenance for demanding industrial environments.

Key features

- Optimized two‑phase flow design: Flow parts and impellers are shaped to reduce clogging and improve handling of solids-carrying fluids.

- Non‑clog impeller options: Available in single- or double-channel designs and in open, semi-open and swirling three‑blade open configurations to match application debris and fiber content.

- Wide material choices: Cast iron, cast steel, stainless steel or wear-resistant high‑chromium cast iron to suit corrosive or abrasive slurries.

- Flexible sealing: Packing seal, mechanical seal or blade power seal options for different media and pressure conditions.

- Bearing lubrication options: Grease, oil lubrication or dual-use arrangements selectable by pump speed and duty.

- Front/rear cover design: Pump head allows maintenance without removing pipeline connections, reducing downtime.

Performance advantages

- Improved cavitation resistance and extended life — reported service life typically 2–3× that of standard pulp pumps.

- Higher hydraulic efficiency — operating efficiency often 3–10 percentage points above average pulp pumps, with potential energy savings of 15–30%.

- Anti‑blocking capability — suitable for conveying higher concentration pulp (general concentrations up to ~6%).

- Compact and lightweight construction for easier installation and reduced foundation requirements.

Typical applications

- Paper mills and pulp processing

- Mining and mineral processing

- Coal handling

- Power plants

- Food processing and sugar production

- Municipal sewage and wastewater

- Bulk slurry transport and general industrial solids–liquid transfer

Notes for specification and selection

- Select materials and sealing arrangements based on slurry abrasiveness, chemical corrosiveness and operating pressure.

- Choose impeller type (open, semi‑open, channel configuration) to minimize clogging for the expected particle/fiber sizes.

- Confirm lubrication and bearing options based on duty cycle and shaft speed.

This pump is intended for industrial customers seeking a durable, energy‑efficient solution for transporting pulp and other solid–liquid mixtures with simplified maintenance and configurable materials and seals.

Product Details

Harmonized commodity

Brand:

kenshine-pump

Country of origin:

China

Industrial sector:

SKU:

SET

GTIN/EAN:

841370

MPN:

LXLZ

Model:

100LXLZ-150-16

Unit type:

Set

Minimum order (MOQ):

1