Mechanical vapor recompression (MVR) evaporator designed for the concentration and thermal treatment of industrial wastewater, emulsions, and aqueous solutions with dissolved or suspended solids. Uses a compressor to recompress the steam generated in the process itself, drastically reducing the need for fresh steam and energy consumption compared to conventional evaporators.

Main Features:

- High energy efficiency: recovery and reuse of latent heat through steam recompression, reducing energy consumption and operational costs.

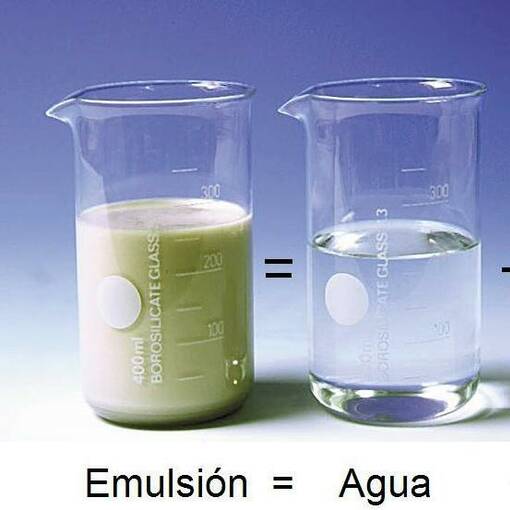

- Effective treatment of emulsions and effluents: capable of concentrating solutions, separating phases, and reducing the volume of sludge for final disposal.

- Industrial construction: design and materials suitable for continuous operation in industrial environments; possibility of fabrication in stainless steel and corrosion-resistant materials depending on the effluent nature.

- Compact and modular operation: compact plant configuration facilitating integration into existing facilities; modular options for phased scaling.

- Control and automation: control systems for managing flow rates, temperature, and pressure, with automatic start/stop functions and alarms for process protection.

- Maintenance and cleaning: designed to facilitate maintenance and cleaning tasks; may include CIP (clean-in-place) options as required.

Typical Applications:

- Treatment of industrial wastewater (textile, chemical, metallurgical, petrochemical, pharmaceutical, food processing).

- Concentration and recovery of emulsions and effluents with high organic content or salts.

- Volume reduction of sludge and liquid by-products before final disposal or valorization.

- Plants seeking to minimize steam consumption and thermal footprint through mechanical recompression technologies.

Advantages for companies:

- Significant reduction in energy OPEX compared to direct steam-fed solutions.

- Lower volume of effluent to treat or dispose, with savings in transportation and final treatment costs.

- Possibility to recover water for reuse in industrial processes, reducing fresh water consumption.

- Flexibility to adapt to different flow rates and effluent compositions.

Options and customization:

- Selection of materials and coatings based on the effluent's aggressiveness.

- Integrable pre-treatment systems (coarse solid separation, degassing, pH adjustment).

- Post-treatment systems for distillate or concentrate according to discharge regulations or reuse requirements.

If you require technical specifications (design flow rate, Brix degrees or % solids in inlet/outlet, compressor power, expected efficiency, or dimensions for plant integration), we can provide them to tailor the solution to your operational requirements.

Product Details

Harmonized commodity

Country of origin:

Spain

Industrial sector: