Commercial reverse osmosis (RO) systems deliver high-purity water by removing suspended solids, dissolved minerals, organic carbon, chemical contaminants and microbiological impurities. Designed for industrial and beverage-sector applications, RO systems produce consistent, low-TDS water suitable for beverage formulation, process makeup, boiler feed, clean-in-place (CIP) water and other production uses.

Key capabilities

- High contaminant removal: effectively reduces dissolved salts, hardness and organic load; when applied for commercial water treatment, RO membranes can reject particles down to about 0.0001 micron.

- Broad contaminant control: lowers levels of chemicals, viruses, bacteria and parasites when used as part of a multi-stage treatment train.

- Consistent output quality: stabilizes input water parameters to improve product consistency and process control in beverage manufacturing.

Typical features (industry standard)

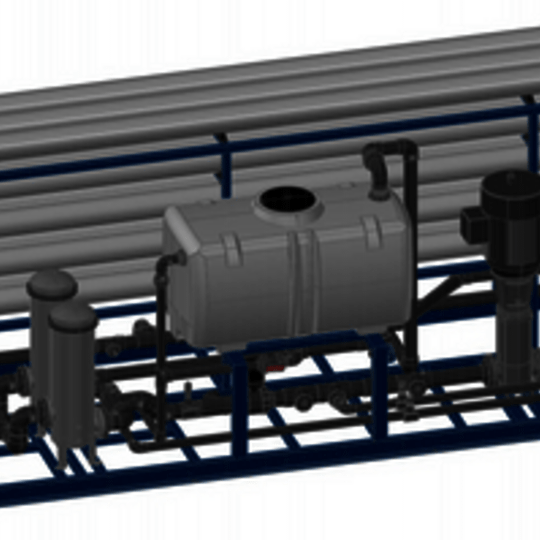

- Multi-stage arrangement: pre-filtration (sediment, carbon), high-pressure pumping, RO membrane modules and optional post-treatment polishing.

- Control and monitoring: integrated control panels or PLCs for pressure, flow and quality monitoring; alarm and shutdown interlocks for process protection.

- Scalability and modularity: systems can be sized and configured to meet required production capacities and to integrate with existing pretreatment or disinfection equipment.

Benefits for beverage industry buyers

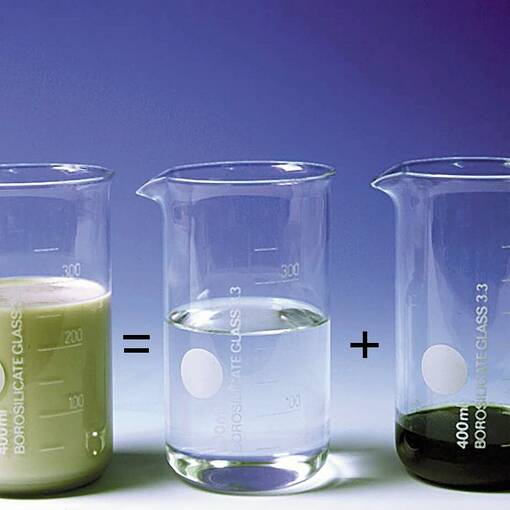

- Product consistency: removes variability in source water that can affect taste, appearance and shelf life.

- Operational reliability: protects downstream equipment (heat exchangers, boilers, filling lines) from scale and fouling, reducing downtime and maintenance.

- Microbiological risk reduction: when combined with appropriate pretreatment and disinfection, helps reduce microbial load entering beverage processes.

Applications

- Ingredient water for beverage formulation

- Process make-up water and boiler feed

- Clean-in-place (CIP) and rinse water

- Bottled water production (as part of a complete purification train)

Options and customization

Systems are commonly offered with configurable membrane arrangements, flow capacities, automated controls, and options for integrated pretreatment or post-treatment (UV, polishing filters, remineralization) to meet product and regulatory requirements. For selection, consider source-water quality, target output quality, required capacity and integration needs with existing plant systems.