A rugged tank-bottom angle valve designed for fast, reliable discharge or sampling from the bottom of reactors, drains and feed vessels. Built for welded or flange installation, this valve minimizes dead space and provides a corrosion- and erosion-resistant sealing solution for demanding process lines.

Key features

- Angle-disc design with outlet angles available in 45°, 50° and 90° to suit piping layouts and drainage requirements

- Integrated construction with the disc opening into the tank to ensure full drainage and rapid material evacuation

- Rotation-resistant stem guidance to ensure pure linear motion of the stem and prevent stem/tip rotation

- Wear-resistant protection plate and alloy sealing surfaces (cermet/overlaid cemented carbide or tungsten paint) for extended life in abrasive or corrosive media

- Auxiliary line sealing to improve sealing reliability under cyclic operation

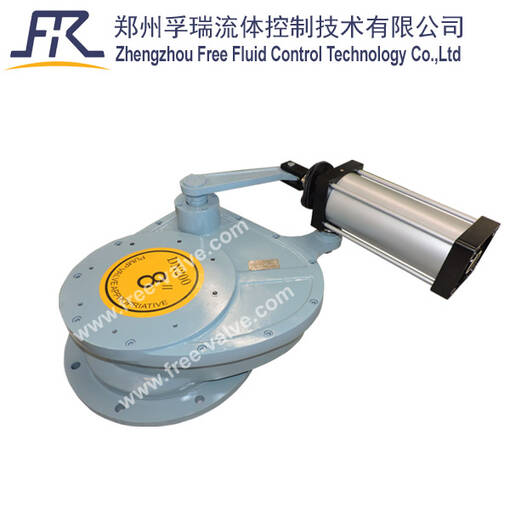

- Available with pneumatic actuation (standard), manual or electric actuation; supports remote control (solenoid) or local operation

Typical specifications

- Flange connection: ASME

- Design standard: ASME

- Pressure range: Class 150 – Class 300

- Size range: DN50 – DN350 (NPS 2 – NPS 14)

- Materials: carbon steel or stainless steel body options; alloy/carbide sealing surfaces

- Connection type: flange (weld or bolt-on flange mounting possible)

- Maximum working temperature: ≤ 425 °C (application-dependent)

- Sealing surface material: alloy / overlaid cemented carbide / tungsten coatings

- Pressure test standards: GB/T 13927, API 598

Applications

Engineered for process industries that require reliable bottom discharge and dead-space-free draining, including petrochemical, alumina and steel plants, polymer processing, mining, pharmaceutical and fine chemicals, and mineral processing.

Advantages for procurement and plant operation

- Reduces product hold-up and simplifies tank draining and sampling

- Hard-faced sealing surfaces and protection plates extend service life in abrasive/corrosive services

- Multiple actuation options and remote-control readiness help integrate the valve into automated systems

- Standard ASME flange dimensions and pressure classes ease installation and replacement in existing piping systems

Model note

- Model: FRFb645Y

For specification sheets, material certificates or to discuss customization (special alloys, surface treatments, actuator packages), request detailed technical data and dimensional drawings from the supplier.