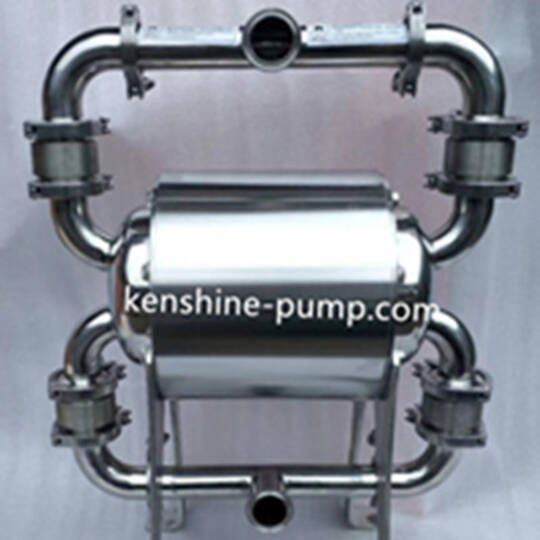

Hygienic air-operated double-diaphragm (AODD) pump engineered for sanitary processing and industrial applications where contamination risk must be minimized. The pump features a seal-less, explosion‑proof design with low shear and self-priming capability, making it suited for food & beverage, pharmaceuticals, alcohol and daily-chemical production lines that require high hygiene standards.

Key features

- Fluid-contact components in stainless steel (options: SS304, SS316, SS316L) manufactured to sanitary/food-grade requirements.

- Precision-cast wet parts with smooth, high-strength surfaces for easier cleaning and improved durability.

- High-roundness valve balls machined for reliable seating and leak-free operation.

- Diaphragm travel optimized to reduce stress on the diaphragm and extend service life.

- Robust four-bolt housing connection and sealing design; actual dry suction capability up to 0–4 m.

- Modular three-section upper/lower cover for flexible installation and maintenance access.

- Integrated diaphragm-retaining block delivering excellent pressure and temperature resistance.

- Wear-resistant stainless steel diaphragm connecting rod for improved corrosion resistance and longer life.

- Air distribution valve with three-way pilot (no O-ring/cylindrical valve) to eliminate dead points, reduce downtime and stabilize flow with lower pulsation.

Performance and applications

- Operates from compressed air; two diaphragms are mechanically linked so they move synchronously to create continuous suction and discharge through alternating one-way ball valves.

- Gentle, low-shear pumping action suitable for shear-sensitive liquids and processed foods.

- Hygienic construction for applications in food & beverage, pharmaceuticals, cosmetics, alcohol/distilling, and other sanitary production lines.

- Easy to maintain with replaceable wear components and a design that simplifies cleaning and inspection.

How it works (brief)

Two symmetrical working chambers each contain a flexible diaphragm. A connecting rod links the diaphragms so they move in sync. Compressed air is alternately introduced to each valve chamber, pushing one diaphragm forward while the opposite diaphragm’s chamber exhausts. The reciprocating motion changes chamber volume and, with two one-way ball valves per chamber, produces continuous suction and discharge. The air distribution valve’s three-way pilot and improved commutation reduce stoppages and provide smoother flow with smaller pulses.

Typical delivered benefits for B2B buyers

- Reduced contamination risk thanks to sanitary materials and construction

- Lower maintenance and downtime with modular design and robust valve/diaphragm components

- Flexible use across hygienic processing lines and chemical-compatible production

- Suitable for applications requiring self-priming and dry-run capability (within stated limits)

For selection, specify required wetted-material grade (SS304/316/316L), required flow and discharge head, and compatibility with your product’s viscosity and particulates to ensure optimal sizing and configuration.