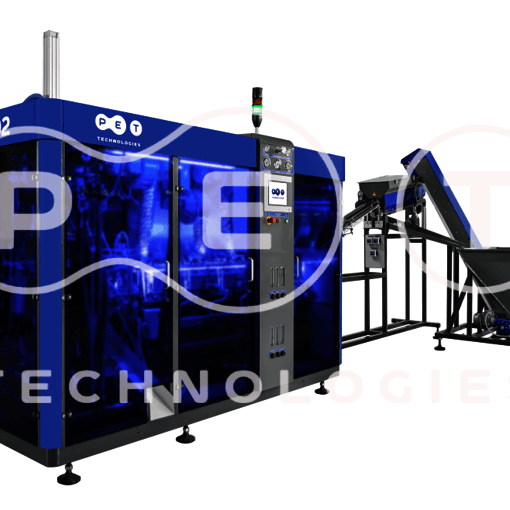

Compact, high-capacity automatic stretch blow moulding machine engineered for manufacturing PET bottles in the 3.0–10.0 L range. The APF-10 delivers up to 2,500 bottles per hour (actual output depends on bottle geometry and mould configuration) and is built for continuous production in beverage and liquid-packaging operations.

Key features

- Production range: suitable for PET containers with volumes from 3.0 to 10.0 liters.

- Throughput: up to 2,500 bottles per hour (dependent on bottle size and mould layout).

- Separate valve block for each mould cavity: independently designed valve assemblies enhance process stability, reduce cross-talk between cavities and simplify maintenance and troubleshooting.

- Fully automatic stretch blow moulding process tailored for medium-to-large format PET containers.

- Regulatory compliance: CE certified and conforms to HACCP requirements for food-contact packaging.

Benefits for processors

- Consistent bottle quality across large-volume formats, supporting beverage and liquid-packaging applications.

- Reduced downtime and faster serviceability thanks to per-cavity valve blocks and a modular design approach.

- Compliance-ready equipment simplifies approvals for food and beverage production lines.

Recommended applications

- Large-format beverage bottles (water, juices) and other liquid packaging where 3–10 L PET containers are required.

Ordering and integration

Request the detailed technical datasheet and integration options from the supplier to confirm expected output for your bottle design, mould cavity count, utility requirements and line integration. Specifications such as mould configuration, cycle parameters and auxiliary equipment will determine final throughput and layout.

Product Details

Harmonized commodity

Brand:

PET Technologies

Country of origin:

Austria

Industrial sector:

Model:

APF-10