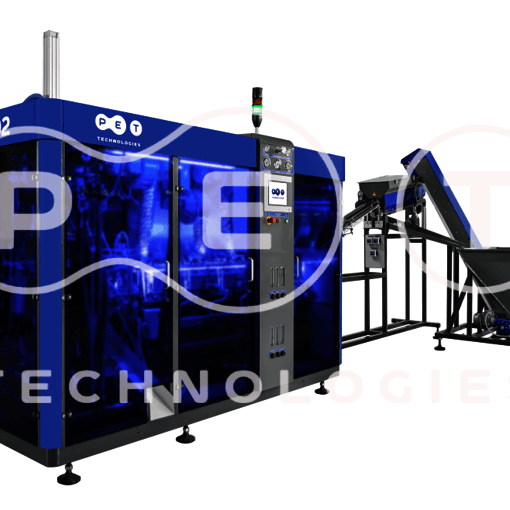

High-capacity automatic PET blow-moulding machine engineered for the high-volume production of large PET bottles (3.0–10.0 L). The unit features two independent blowing stations that can run different bottle formats simultaneously, enabling flexible production of multiple bottle sizes on a single line. The machine is delivered with a CE certificate (as stated by the supplier).

Key features and benefits:

- High throughput: 1,600 bottles/hour for 3–8 L bottles; 700 bottles/hour for 10 L bottles.

- Wide format range: compatible with bottle volumes from 3.0 to 10.0 litres.

- Dual independent blowing units: produce two formats in parallel to increase flexibility and reduce changeover time.

- Robust pneumatic system: blowing pressure up to 30 bar with a low-pressure circuit at 8–10 bar.

- Documented utility consumption (example for 5.0 L bottle): high-pressure air demand 5.0 m3/min; low-pressure air demand 1.3 m3/min.

- Cooling requirements: cooling liquid temperature 7–9 °C.

- Electrical requirements: 400 V / 50 Hz supply; installed power 43 kW.

- Plant footprint and mass: overall dimensions 9,200 × 2,200 × 2,720 mm; weight 4,600 kg.

Typical applications: large-capacity PET bottles for water, edible liquids and other packaging uses in the packaging industry (suitable for inline production where medium-to-high hourly outputs are required).

Ordering and pricing: final price depends on selected configuration, optional accessories and delivery terms. Contact the supplier for detailed technical drawings, certifications, lead time and optional automation or tooling packages.