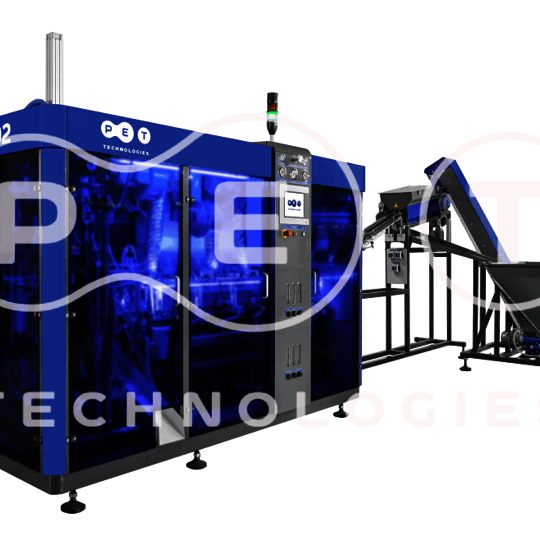

High-speed automatic PET bottle blowing machine designed for medium-capacity production of PET containers (0.25–2.0 L). Built for industrial packaging lines, it delivers consistent, energy-efficient blow-molding with a patented mold-closing system that achieves up to 1,500 bottles per hour from a single mold (rated capacity 3,000 bottles/hour under standard test conditions).* CE conformity is indicated for safe operation in regulated markets.

Key benefits

- Reliable automatic operation for continuous production runs

- Patented mold closing mechanism to maximize throughput per mold

- Compact footprint for its output class and straightforward integration into packing lines

- Engineered for standard 35 PCO preforms and common PET packaging formats

Technical specifications

- Rated output: 3,000 bottles/hour* (note: 1,500 bph achievable per mold via patented mold-closing system)

- Bottle volume range: 0.25–2.0 L

- Blowing pressure: up to 40 bar

- Low pressure: 8–10 bar

- High-pressure air demand (example for 1.5 L bottle): 3.6 m3/min

- Low-pressure air demand (example for 1.5 L bottle): 1.3 m3/min

- Cooling liquid temperature: 7–9 °C

- Electrical supply: 400 V / 50 Hz

- Installed power: 33 kW

- Overall dimensions (L×W×H): 6,400 × 2,800 × 2,300 mm

- Machine weight: 2,350 kg

Recommended for

- Beverage and liquid-food packaging producers scaling to mid-level outputs

- Contract manufacturers and packagers requiring compact, high-throughput PET blow molding

Notes

- Actual output depends on preform type, mold configuration and production parameters. The 3,000 bph rating is based on standard test conditions; consult supplier for validation with your preforms and molds.

- Price depends on selected configuration, tooling and order volume.

*Example rating: 1.5 L bottle produced with 35 PCO preform.

Product Details

Harmonized commodity

Country of origin:

Ukraine

Industrial sector: