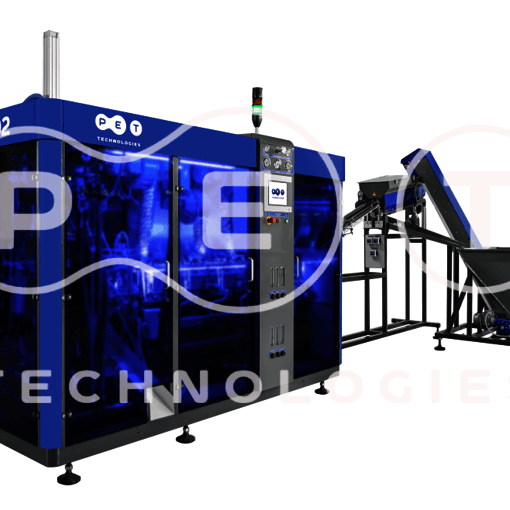

High-speed automatic PET bottle blow-moulding system engineered for continuous production of 0.2–2.0 L containers. The machine delivers a rated output of 6,000 bottles per hour and incorporates a patented mold‑closing system that achieves up to 1,500 bph from a single mold cavity, enabling flexible scaling of throughput by using multiple cavities.

Key features

- Production capacity: 6,000 bottles per hour (total)

- Bottle volume range: 0.2–2.0 L (suitable for standard PET preforms)

- Patented mold closing system: up to 1,500 bph per mold cavity

- Certifications: CE certificate; conforms to HACCP requirements

- Application: Designed for high-volume production of beverage, water, edible-oil, dairy and other PET containers

Benefits for manufacturers

- High throughput for large production runs

- Modular mould performance that scales output via additional cavities

- Compliance with CE and HACCP supports use in food and beverage production lines

Notes

- Final machine configuration (number of cavities, mold types, automation and peripheral equipment) determines exact output and integration requirements. Request the technical datasheet or quotation for detailed electrical, pneumatic, footprint and installation specifications, and available options.

Product Details

Harmonized commodity

Country of origin:

Austria

Industrial sector:

Model:

APF-6004