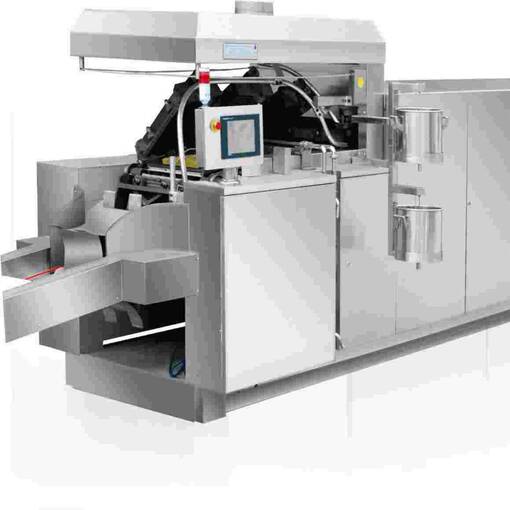

Industrial equipment for the production and processing of ice cream and dairy mixtures, designed for continuous or batch production in workshops, artisanal ice cream shops, and food processing plants. The range includes batch freezers and continuous freezers (freezers), pasteurizers, ripeners, homogenizers, and other auxiliary machines necessary in the production chain.

Key features and advantages:

- Hygienic construction in stainless steel (food-grade surfaces in contact with the product), designed to facilitate cleaning and meet sanitary requirements.

- Precise process control: digital/PLC control panels for adjusting temperatures, pasteurization times, homogenization pressure, mixing speed, and ripening cycles.

- Capacity flexibility: options ranging from small units for artisanal establishments to high-performance lines for industrial production (specify L/h or kg/h according to needs).

- Cooling systems: air- or water-cooled variants, with compressors and evaporators sized to achieve the desired texture and temperature.

- Safety and maintenance features: protection circuits, easy access to components for maintenance, and CIP (Cleaning In Place) cleaning capability according to the model.

- Product quality: controlled homogenization and pasteurization to improve texture, uniform air incorporation (overrun), and mixture stability.

Technical specifications recommended to request from the supplier:

- Rated capacity (L/h or kg/h) and type of production (batch / continuous).

- Homogenization pressure (bar) and pressure reduction ratio.

- Temperature range and control for pasteurization and ripening, as well as retention times.

- Cooling type (air/water), energy consumption, and electrical requirements (V/Hz/phase).

- Materials in contact (e.g., AISI 304/316), surface finish, and applicable hygienic-sanitary certifications.

- Automation options, batch records (traceability), and compatibility with HACCP systems.

- Installation requirements, dimensions, and weight for handling and assembly.

Associated services and post-sale support:

- Commissioning and staff training in operation and cleaning.

- Preventive maintenance contracts and supply of critical spare parts (seals, pumps, valves, gaskets).

- Customizations and adaptations according to specific formulations (sorbets, dairy ice creams, low-fat, vegan).

Typical clients and uses:

- Artisanal ice cream shops and franchises.

- Dairy processing plants and frozen dessert manufacturers.

- Co-packing companies and contract production businesses.

To obtain an accurate quotation, please provide: required capacity, type of final product (creamy, soft-serve, packaged), automation needs, space constraints, and available electrical power. With this information, the most suitable machine or line can be proposed, along with estimated delivery times, installation, and total cost of ownership.