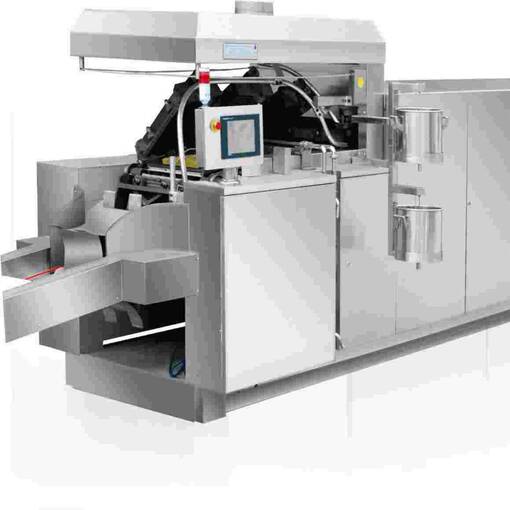

Electromagnetic detection system designed for integration into conveyor belts to perform quality control in food processing. Ideal for reliable detection of metal fragments (ferrous, non-ferrous and stainless steel) in products in transit, allowing minimization of rejections, protection of process equipment and ensuring compliance with food safety standards.

Key features:

- Multi-metal detection: Detects ferrous, non-ferrous and stainless steel particles using coil technologies and adaptive signal processing.

- Inline integration: Designed for mounting above or around the conveyor belt with quick height and width adjustments for different product formats.

- Hygienic and robust design: Industrial construction casing (optional in AISI 304/316 stainless steel), with easy-to-clean finish and IP protection ratings for food production environments.

- Easy configuration and calibration: Control interface with product-adjustable parameters (sensitivity, belt speed, step size) and autotuning functions to maintain sensitivity with product changes.

- Outputs and control: Output signals for integration with PLC/SCADA, visual and acoustic alarms, and automatic rejection options (pushers, blowers, diverters) or line stoppage.

- Data management: Event logging, rejection counters and communication options (digital ports, Ethernet, OPC/Modbus according to configuration) for traceability and quality.

Typical applications:

- Food industries (meat, dairy, bakery, fruits and vegetables, processed products)

- Packaging centers and packaging lines

- Inspection and quality control plants

Customer benefits:

- Reduction of metal contamination risks and customer complaints

- Protection of machinery in later process stages

- Improvement of traceability and compliance with HACCP plans and quality audits

- Increased efficiency by automating detection and rejection

Purchase and installation considerations:

- Select appropriate sensitivity based on product type, particle size and orientation

- Confirm compatibility with conveyor belt speed and step width

- Evaluate hygiene requirements (IP certification, stainless steel finishes) if working with washdowns and wet environments

- Define rejection method (mechanical, pneumatic, electronic) and integration requirements with existing control systems

Associated options and services (depending on supplier):

- Variants for different belt widths and step heights

- Automatic rejection kits and mechanical adapters

- Installation, commissioning, and in situ calibration services

- Preventive maintenance contracts and periodic calibration

If desired, I can adapt this description including specific technical specifications (minimum sensitivity in mm, maximum belt width, maximum speed, electrical power requirements) once you have those data or the equipment's technical sheet.

Product Details

Country of origin:

Argentina

Industrial sector: