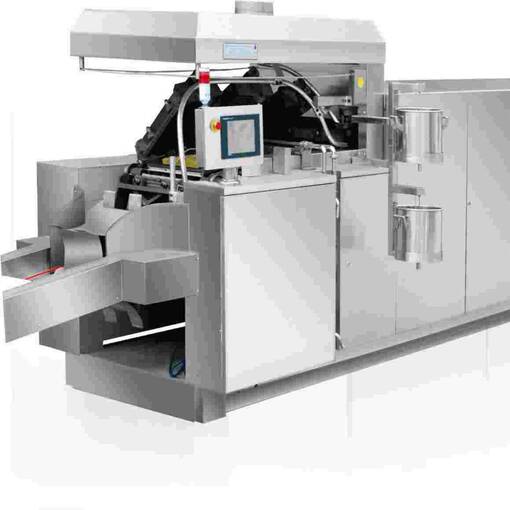

Triblock machine for rinsing, filling, and capping bottles designed for food processing. Performs preliminary rinsing, free-fall filling or gasified mode filling (suitable for carbonated beverages), and closure via capping or corking. Compatible with glass, PVC, and PET packaging.

Main Features:

- 3-in-1 function (rinse + fill + cap) to optimize space and logistics in bottling lines.

- Completely sanitary design, suitable for liquid food products and engineered to facilitate hygiene and maintenance.

- Filling modes: free-fall for non-carbonated liquids and gasification option for carbonated beverages.

- Versatile capping: accommodates corks, threaded metal caps, and threaded plastic caps; possibility of incorporating Italian-origin capping solutions.

- Compatible with bottles made of different materials (glass, PVC, PET) and adaptable to various heights and diameters via mechanical adjustments.

B2B Buyer Benefits:

- Integrates three processes into a single machine, reducing the need for separate equipment and handling time.

- Suitable for production lines of water, juices, carbonated beverages, wines, and other liquid food products.

- Configurable according to the type of packaging and closure required; facilitates implementation in existing bottling plants.

Options and Considerations:

- Specific configuration can be requested for the type of closure and required production speed.

- Compatibility with bottle formats and final product regulatory requirements should be verified.

If detailed technical specifications (flow rate per hour, dimensions, electrical consumption, or integration requirements) are needed, request a technical sheet or customization conditions for a quote.

Product Details

Harmonized commodity

Country of origin:

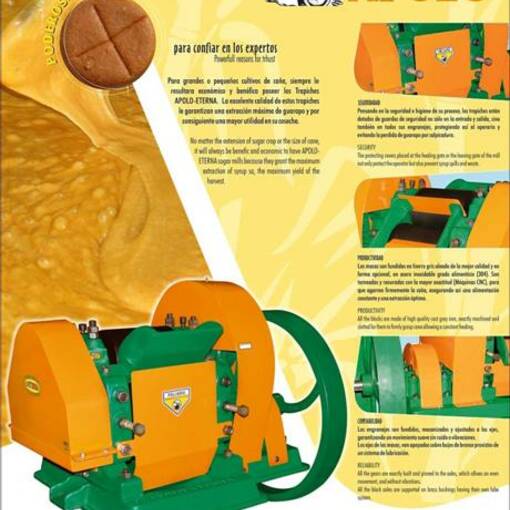

Argentina

Industrial sector: