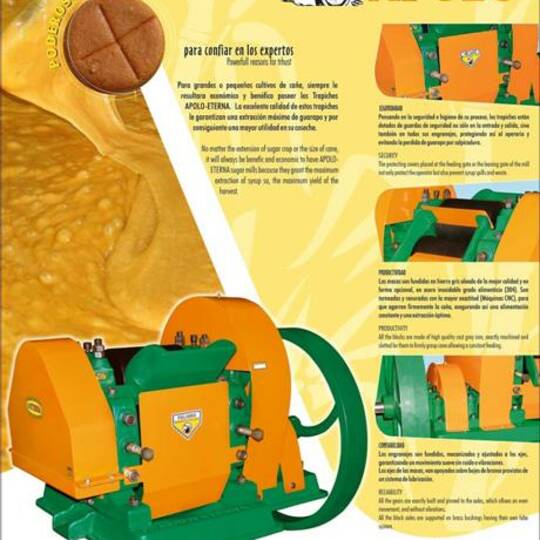

Industrial equipment designed for sugarcane juice extraction via pressing or crushing mechanisms. Built with continuous production processes in mind, the trapiche is suitable for sugar mills, sugar factories, distilleries, panela processors, and biomass processing plants.

Key Features

- Pressing/roller system: single or multiple roller versions available in manual, motorized, or direct drive configurations.

- Materials and construction: carbon steel or stainless steel structures in areas in contact with juice, reinforced for heavy-duty operation and high durability.

- Hygienic and easy-to-clean design: removable access panels and covers for washing and maintenance, designed to meet basic food hygiene requirements.

- Crushing/pressure adjustment: mechanisms to regulate space between rollers or pressing force, optimizing extraction according to cane variety and moisture content.

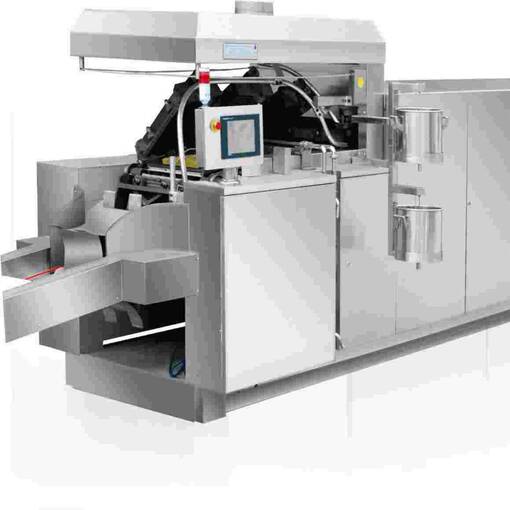

- Integration and automation: possibility to integrate feeding hoppers, conveyors, cleaning systems, and electrical controls for continuous operation and performance monitoring.

- Spares and service: wear parts (rollers, grippers, bearings, belts) available for preventive and corrective maintenance.

Industrial Applications

- Sugarcane juice extraction for sugar, panela, rum, ethanol, and other derivatives production.

- Preliminary processing for fermentation or physicochemical treatment.

- Use in pilot plants and medium to large-scale production lines.

B2B Buyer Benefits

- Increased extraction performance due to precise adjustments and robust design.

- Reduced downtime through simple maintenance and spare parts availability.

- Configuration flexibility (manual, motorized, integration with existing lines).

- Design focused on continuous operations and high production output.

Options and Customization

- Adjustable capacities and dimensions based on raw material flow and available space.

- Specific materials and finishes for sanitary or corrosive environments.

- Electric, hydraulic, or diesel engine drive systems according to plant energy availability.

Associated Services

- Technical assistance for model selection based on required capacity and operating conditions.

- Installation, commissioning, and training for operational personnel.

- Preventive maintenance contracts and spare parts supply.

If you need technical specifications (tons per hour performance, motor options, dimensions, or integration blueprints), specify the expected processing capacity and usage context, and we will provide a detailed recommendation and quotation.

Product Details

Country of origin:

Colombia

Industrial sector: