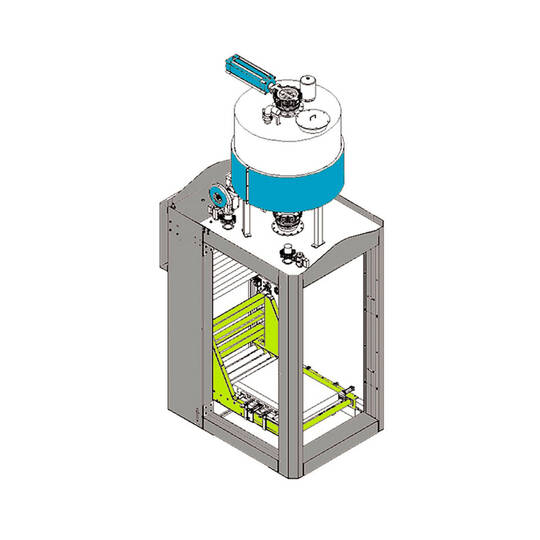

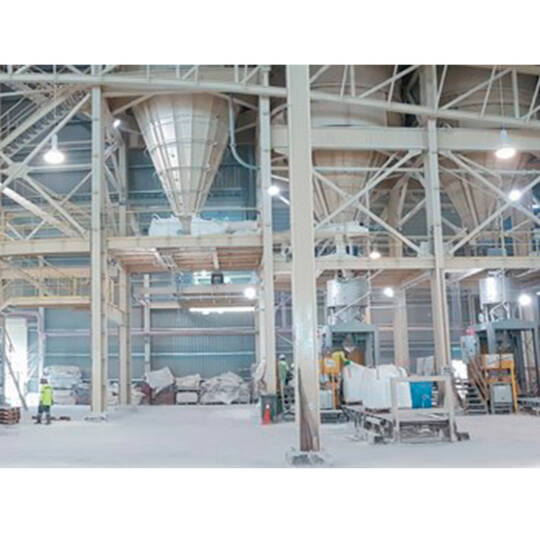

Modular stations for filling and handling big-bags, custom-designed and manufactured for industrial processes. Systems adaptable to different levels of automation (semi-automated to fully automated) and integrable with Industry 4.0 solutions and industrial robots, applying Best Available Techniques (BAT).

Key features:

- Modular configuration: options of 1, 2, or 3 filling stations that facilitate scalability according to production needs.

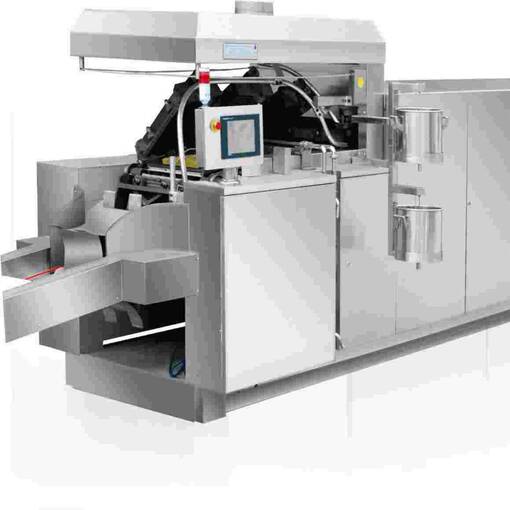

- Robotic integration: possibility of adding a robot for handling and positioning of big-bags, optimizing time and safety.

- Theoretical production (dependent on product, configuration, and automation level):

- 1 station, semi-automated: 30–60 big-bags/h

- 2 stations, semi-automated: 60–120 big-bags/h

- 3 stations, semi-automated: 90–180 big-bags/h

- Product customization: design of hoppers, ducts, and dosing systems according to fluidity, granulometry, and characteristics of the material to be packaged.

- Control and traceability: control systems compatible with smart manufacturing environments for production monitoring, integration with PLC/SCADA, and process data capture.

- Prior validation: tests with your product in our laboratory to determine the optimal configuration and expected actual capacity.

Benefits for your plant:

- Increased productivity and reduced cycle times through automation and robotization.

- Less manual handling and greater operational safety.

- Custom design that facilitates adaptation to existing spaces and processes.

- Process data available to optimize operations and predictive maintenance.

Options and associated services (consult availability): custom design and engineering, commissioning, operator training, integration with existing lines, and preventive maintenance.

Product Details

Harmonized commodity

Country of origin:

Spain

Industrial sector:

Minimum order (MOQ):

3