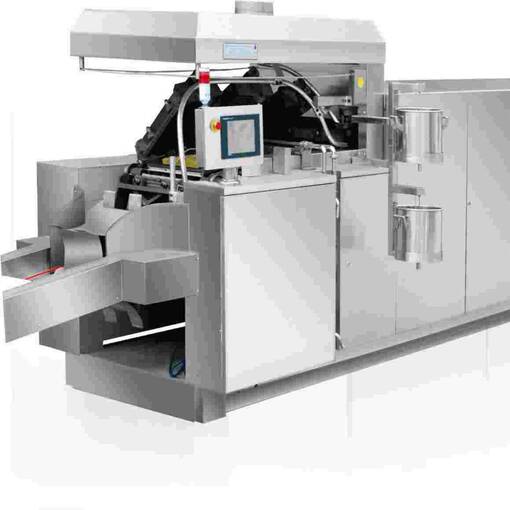

Automatic churro extrusion machine designed for industrial and artisan production. Ideal for factories, bakeries, and churro shops that need an easy-to-use, programmable machine capable of maintaining uniformity in repeated batches.

Main Features:

- Programmable digital control panel: allows adjusting and memorizing parameters (length, output speed, and format) to ensure uniformity between batches.

- Available hopper capacities: 2.75 L or 3.75 L, depending on production demand.

- Three output configurations (models according to format):

- Model 1: straight and hollow churro.

- Model 2: straight, hollow, and loop churro.

- Model 3: straight, hollow, and donuts.

- Flow rate and performance: average production of 68 g/s (approximately 244.8 kg/h), with the possibility to adjust the size and weight of each piece.

- Options for large-scale production: 3.75 L hopper with 80 mm dough output (alternative to standard 45 mm output) to allow four or five-pointed star nozzles and larger-volume pieces.

- Product versatility: besides churros, it can produce pigs in blankets, striated donuts, sticks, sweet churros, and other formats; it is possible to manufacture molds or nozzles with custom designs.

- Designed for ease of use: simple handling and intuitive programming.

Benefits for B2B buyers:

- Increases productivity while maintaining product consistency.

- Reduces reliance on specialized labor thanks to automation and parameter memory.

- Scalable according to needs: suitable for small churro shops as well as industrial production (including frozen or distribution churros).

Typical applications:

- Industrial production of churros and baked/fried snacks.

- Bakeries and restaurant chains requiring uniform, reproducible pieces.

- Frozen and distribution companies requiring high throughput and large-diameter nozzles.

Note: consult technical specifications and nozzle options to choose the most suitable model and output configuration for your production line.