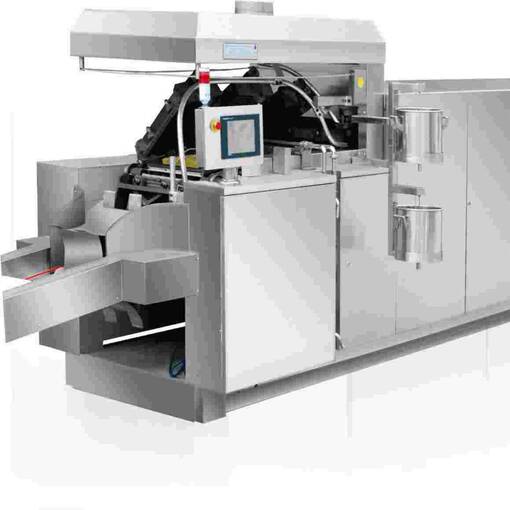

Dough mixer designed for the treatment of soft doughs used in the professional preparation of churros, balls, fritters, and other fried or battered products. Optimizes heating and mixing of ingredients within the machine itself to achieve homogeneous and repeatable textures in high-demand processes.

Main features:

- Double boiler system that allows heating liquids and dissolving ingredients directly in the mixer, reducing processing times and external handling.

- Digital thermostat with temperature adjustment and acoustic signal when the programmed heating point is reached.

- Fixed paddle for mixing that prevents trapping risks and allows the hand to be inserted into the container to check the texture safely.

- Removable container that facilitates dough pouring and transferring, speeding up service or filling of frying equipment.

- Automatic disconnection of heating elements when the container is overturned, protecting the equipment and the operator.

- Safety switches that prevent automatic startup after a power outage; the equipment requires manual reactivation to resume operation (compliance with CE 98/37/CEE – Machine Safety regulations).

- Available in two models with different capacities to adapt to variable production needs.

Advantages for businesses:

- Improves dough uniformity and final product reproducibility, ideal for bakeries, churrasco shops, caterings, and primary industrial production.

- Reduces handling of hot ingredients and intermediate steps, increasing safety and operational efficiency.

- Designed for quick cleaning and maintenance (removable container and fixed paddle).

Recommended applications:

- Production of churros, fritters, balls, and fried or semi-liquid doughs.

- Professional kitchens, small/medium production lines, and retail businesses requiring continuous production throughput.

Note: consult the technical specifications of the specific model (capacities, power ratings, and dimensions) to select the version suitable for your workflow.