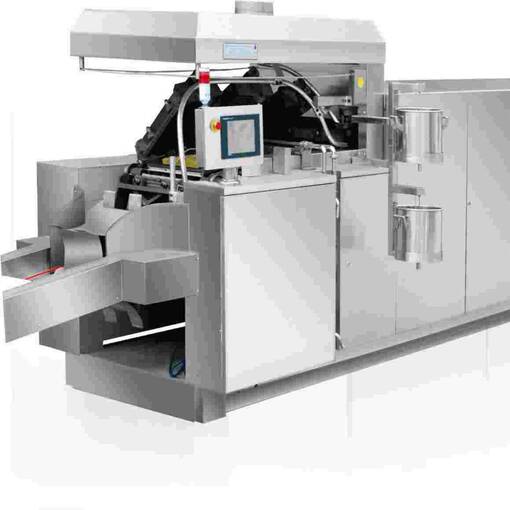

Tunnel/belt shot blasting machine designed for the treatment of natural and artificial stone surfaces (marble, granite, terrazzo) and also applicable to pavements and concrete elements. Based on turbine shot blasting technology, this equipment allows the achievement of uniform and repeatable finishes for industrial and large-scale finishing processes.

Main Features:

- Process: turbine shot blasting for surface cleaning and texturing.

- Available finishes: honeycombed, flamed, and aged, adaptable according to abrasive and setup.

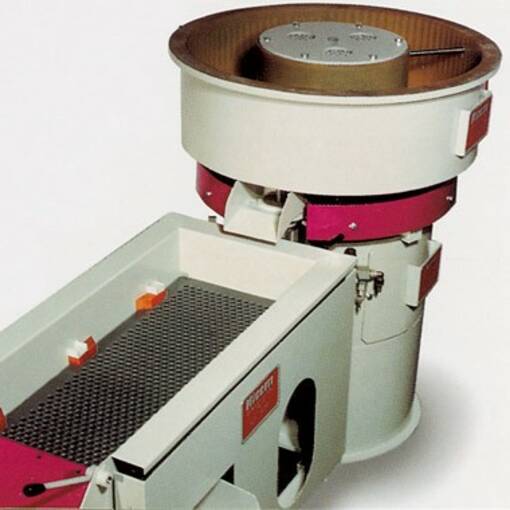

- Shot blasting configuration: possibility to blast the upper surface, lower surface, or both, depending on the equipment setup.

- Input and transportation: configurable inlet opening; standard designs from 600 mm width and adaptable to larger sizes according to the project.

- Industrial design: conceived for continuous operation in production lines with integration capabilities into production chains.

- Maintenance and spare parts: manufactured by a supplier with extensive experience and an international support network and spare parts inventory.

Benefits for the client (B2B):

- Uniform and controlled surfaces, improving the final quality of parts and pavements.

- Increased roughness to enhance adhesion of subsequent treatments (paints, sealants, adhesives).

- Reduction in time and labor costs compared to manual finishing processes.

- Versatility for different materials and thicknesses through adjustment of abrasive, turbines, and transportation speed.

Options and customization:

- Belt/inlet width adapted to the geometry of the part.

- Turbine configuration and power according to the required aggressiveness of the treatment.

- Dust extraction and filtration systems compatible with industrial regulations.

- Integration with automatic controls and conveyor or roller feeding systems.

Common applications:

- Manufacturers of marble and granite countertops and slabs.

- Concrete pavements and prefabricated concrete industries.

- Stone finishing and restoration workshops.

If you need detailed technical specifications (performance per hour, consumption, complete dimensions, or installation requirements), they can be defined based on the configuration and required production flow.