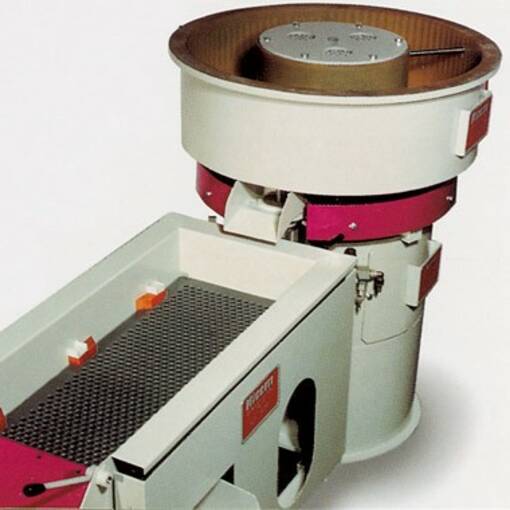

Used sandblasting machine designed for processing small parts and spot operations on larger pieces. It consists of an automatic rotating drum (drum) for continuous processing of small parts and an integrated manual station for tasks requiring individual handling or slightly larger parts. Allows use of different abrasives (white corundum, brown corundum, microspheres) depending on the finish and required cleaning aggressiveness.

Key features:

- Automatic system with rotating drum for cleaning, deburring, and surface preparation of small parts.

- Integrated manual station for sandblasting larger parts or for adjustment and finishing work.

- Compatibility with various types of abrasives: white corundum, brown corundum, and microspheres (selection based on application).

- Used equipment; ideal for production lines, spare parts workshops, and industrial maintenance.

- Wide internal useful dimensions (details not specified in the advertisement — consult the technical sheet if exact measurements are needed).

Recommended applications:

- Cleaning and deoxidation of metal parts.

- Removal of burrs and casting excesses.

- Surface preparation prior to painting or coating.

- Restoration and finishing of parts in automotive, aerospace, metallurgical, and component manufacturing sectors.

Condition and commercial considerations:

- Second-hand machine; prior inspection and verification of operational conditions is recommended (pumping/air system, drum condition, nozzles, and sandblasting chamber).

- Accessories such as dust extraction systems, filters, or compressors are not detailed in the advertisement; it is advisable to evaluate and, if necessary, integrate suction and filtration equipment in accordance with local regulations.

- Safety use: operate with appropriate personal protection (respiratory, ocular, and auditory) and in compliance with industrial safety standards.

If you need additional technical specifications (exact internal dimensions, power, manufacturing year, or maintenance history), request the technical sheet or inspection report for evaluation at your plant.

Product Details

Harmonized commodity

Brand:

ABRASIVOS Y MAQUINARIA

Country of origin:

Spain

Industrial sector: