We offer tailor-made solutions for the dosing and weighing of bulk solid and liquid materials, designed to integrate into industrial processes and optimize accuracy, traceability, and productive efficiency.

Key features and capabilities:

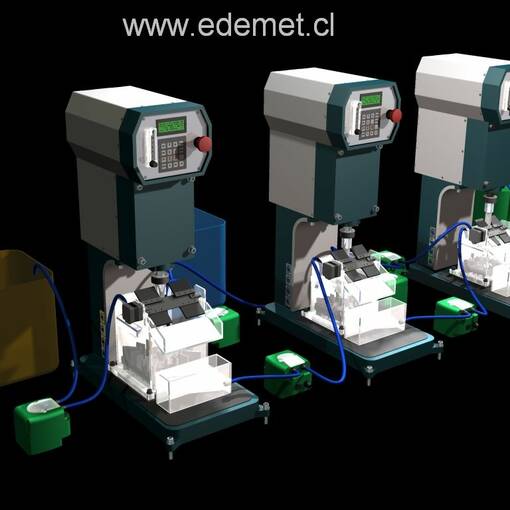

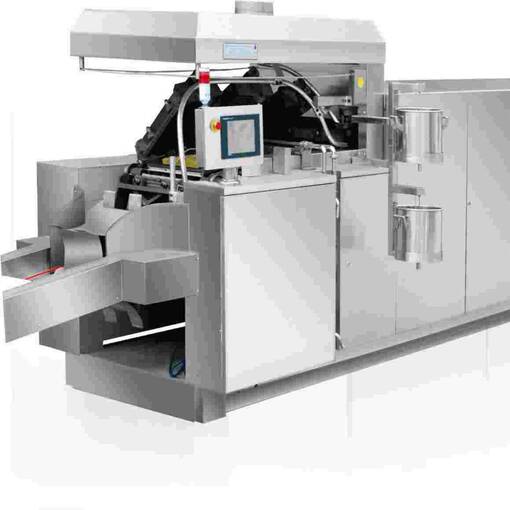

- Modular systems or turnkey complete installations, adapted to the needs of each plant.

- Weight-based dosing for bins, silos, and tanks, with real-time visualization of content and automatic filling/emptying control.

- Support for solid materials (powders, granules, pellets) and liquids (viscous or fluid), with flow rate adjustments and dosing tolerances.

- Typical functions: loss-in-weight weighing, gain-in-weight weighing, batch/recipe dosing, flow control, and weight-based filling.

- Integration with PLC/SCADA for centralized control, data recording, and batch traceability.

- Robust design adaptable to industrial requirements: options for different capacities, precision ranges, and process conditions.

Benefits for your plant:

- Greater accuracy in product formulation and reduced raw material waste.

- Process automation that reduces operating time and manual errors.

- Flexibility to scale up or reconfigure production lines according to demand.

- Improved traceability and quality control through automatic weighing and batch recording.

Customization and service:

Each project is developed following a technical study of your processes (material type, required capacity, location of bins/tanks, and environmental conditions). Systems ready for installation are delivered with calibration, validation, and commissioning options according to customer specifications.

To receive a technical and economic proposal, please provide basic information such as: material type, flow rate range, dosing tolerance, bin or tank capacities, and integration requirements with existing automation.