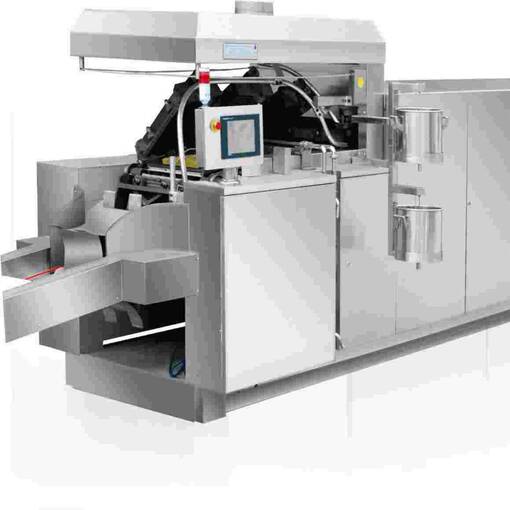

Industrial pelletizing presses designed to compact and convert fibrous and granular materials into homogeneous pellets using a pelletizing matrix. Suitable for animal feed production lines, wood pelletizing plants, straw processing, and for the utilization of various types of waste (e.g., NFU - tire waste, RSU - municipal solid waste), as well as for other industrial process raw materials.

-

Main applications:

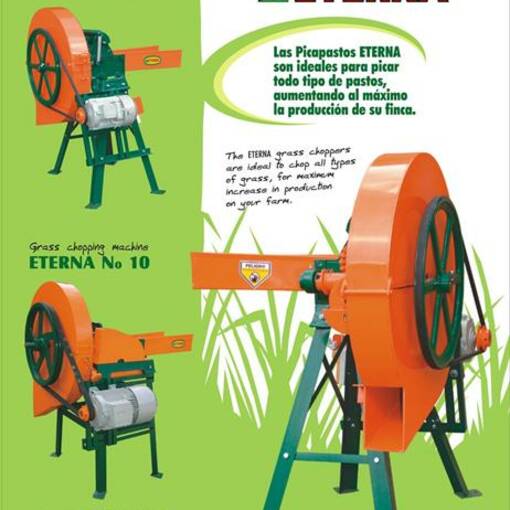

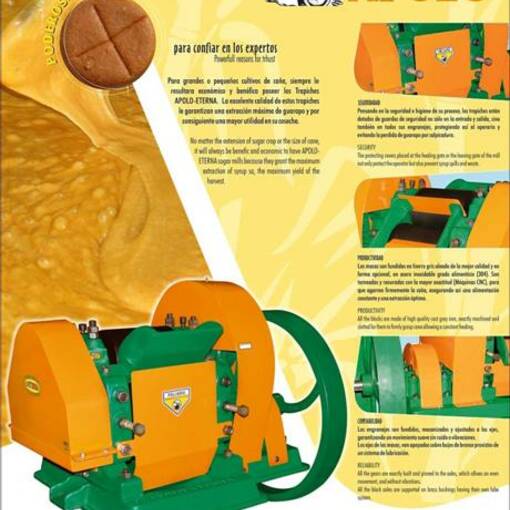

- Production of balanced feed and livestock feed.

- Biomass pelletizing: wood, wood chips, straw, and agricultural by-products.

- Valorization and compaction of industrial or urban waste for energy use or waste management.

-

Key features and performance:

- Matrix system for uniform pellet formation and density control.

- Design oriented for integration into complete plants (possibility of supplying lines and turnkey solutions).

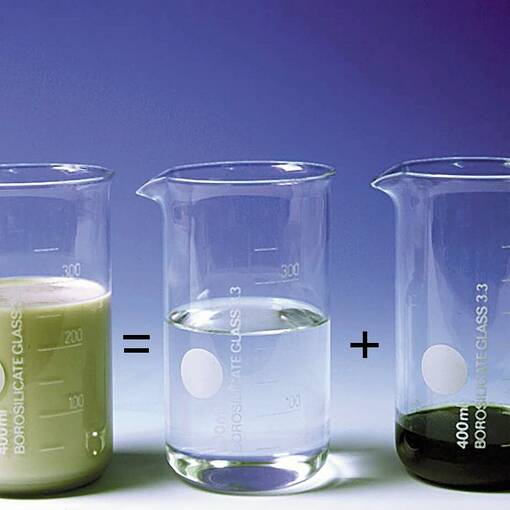

- Suitable for a wide variety of raw materials, with options for prior conditioning (grinding, drying, mixing) and integration with treatment processes.

- Industrial construction designed for continuous operation and accessible maintenance.

-

Advantages for B2B buyers:

- Scalability: configurations and sizes tailored to required production capacity.

- Process flexibility: support different formulations and waste materials to transform them into uniform pellets.

- Volume reduction and improved handling and transportation of the compacted material.

-

Associated services (depending on the project):

- Engineering and design of complete plants.

- Supply of equipment and turnkey installation.

- Adaptation to production requirements and final product quality specifications.

If you need technical specifications (capacity in t/h, power, dimensions, types of matrix or service requirements), detailed data can be provided based on the configuration and the material to be processed.