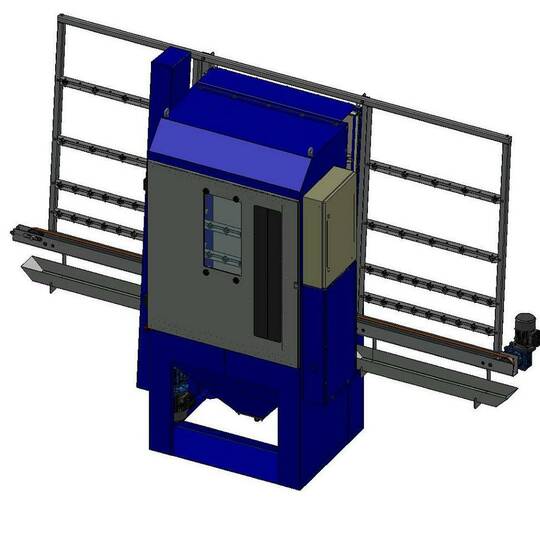

Industrial equipment for sandblasting and polishing flat glass, designed for repetitive and high-quality processes in production lines or specialized workshops. Available in manual and automatic configurations and can be customized to meet specific dimensions, work pace, and finishing requirements.

Main features:

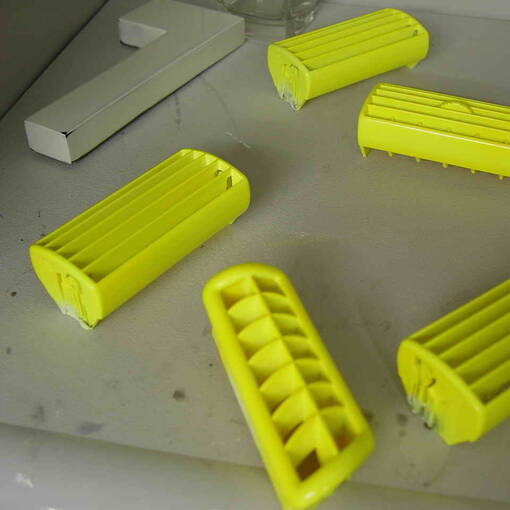

- Preparation and finishes: designed for sandblasting, polishing, and texturing of flat glass surfaces.

- Configurations: manual versions for operator use and automatic/semi-automatic versions integrable into production lines.

- Rugged construction: frame and coatings made with wear-resistant materials and parts to increase service life in abrasive environments.

- CAD/3D design: developed using 3D technology that improves precision, repeatability, and manufacturing cost optimization.

- Customization: possibility to adjust dimensions, clamping systems, projection parameters, and automation according to the specific application.

Common options and accessories (customizable according to the project):

- Abrasive recovery and recycling systems.

- Integration of transportation and handling for automated production.

- Safety and ergonomics elements for manual work.

- Service doors, viewers, and controls adapted to the process.

Advantages for the buyer:

- Solution specifically designed for flat glass treatment, providing consistent and controllable finishes.

- Flexibility for custom projects, both in small batches and industrial installations.

- Increased durability thanks to wear-resistant materials and maintenance-friendly design.

Associated services:

- Project engineering, customized design, and supply of complete equipment.

- Technical service and supply of spare parts to ensure productive continuity.

For projects or detailed technical specifications, request a needs assessment to receive a proposal tailored to the required process, capacity, and finish.