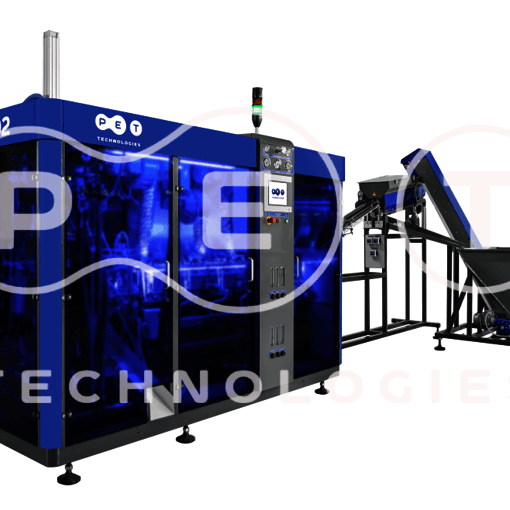

High-output automatic blow-moulding machine designed for continuous production of PET bottles and plastic containers. The APF-Max series integrates a short-wave near-infrared (NIR) heating system to shorten preform heating time and reduce energy consumption, while delivering stable, high-speed blowing performance suitable for beverage, water, edible-oil and household-chemicals bottle production lines.

Key features

- Short-wave near-infrared (NIR) heating system for faster, more energy-efficient preform heating

- Fully automatic operation suitable for inline production with high uptime

- Model range to match required output: APF-Max 8, APF-Max 6 and APF-Max 4

- Robust frame and compact footprint for industrial production environments

Technical specifications (model-dependent)

- Output (bottles/hour): APF-Max 8 — up to 14,000; APF-Max 6 — up to 10,000; APF-Max 4 — up to 7,000

- Blowing pressure: up to 40 bar

- Low pressure: 8–10 bar

- Cooling liquid temperature: 7–9 °C

- Voltage supply: 400 V / 50 Hz

- Installed power: APF-Max 8 — 140 kW; APF-Max 6 — 110 kW; APF-Max 4 — 80 kW

- Overall dimensions (L×W×H): 9,520 × 3,300 × 3,200 mm

- Machine weight: approx. 10,000 kg

- Bottle volume: configurable by option (model- and tooling-dependent)

Benefits for B2B buyers

- High throughput: supports large-scale production targets with stable cycle times

- Energy efficiency: NIR heating reduces electrical consumption and shortens heat-up cycles

- Scalable: three model sizes let you match capacity to demand and floor space

- Industry-ready: designed for heavy-duty, continuous operation and easy integration into existing lines

Options & integration notes

- Bottle volume, tooling, and exact air consumption depend on the chosen configuration and the target bottle geometry; consult the technical datasheet or specification sheet for tooling, air consumption and option details

- Typical applications include PET beverage bottles, water and liquid containers, and other blow-moulded plastic packaging

For precise layout planning, utilities sizing and integration (air, cooling, electrical), review the machine datasheet and specify the target bottle volume and cycle parameters to confirm exact utility demands and tooling requirements.

Product Details

Harmonized commodity

Brand:

PET Technologies

Country of origin:

Austria

Industrial sector:

Model:

APF-Max