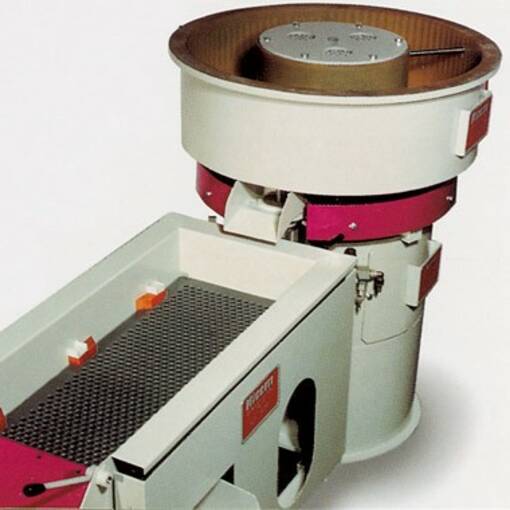

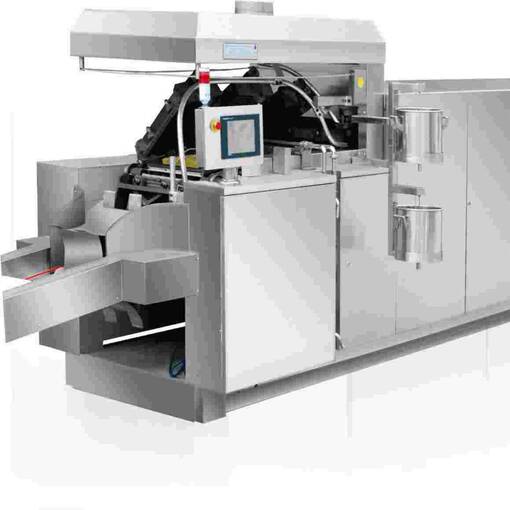

Industrial shot blasting machine of tape (drum) type designed for the treatment and cleaning of small and medium-sized parts in continuous production. The machine allows controlled impact and rubbing between parts to remove sand, oxides, burrs, and prepare surfaces before painting, assembly, or machining processes.

Main Features:

- Continuous drum/tape operation; the tape can be manufactured in rubber or steel depending on the type of parts and required aggressiveness.

- High productivity: suitable for blasting large volumes of parts in short cycles.

- Robust construction intended for foundry and heavy work environments; design aimed at facilitating maintenance and access to spare parts.

- Option to integrate auxiliary equipment: loading skip for containers, discharge conveyor at the drum exit, and other modular options according to the production process.

- Wide availability of spare parts and global technical support backed by the manufacturer's experience since 1970.

Typical Applications:

- Foundry and desilication of iron, steel, and other metal parts.

- Removal of burrs, oxides, and scales.

- Surface preparation for subsequent treatments (painting, coating, welding).

Standard models and capacities (series TG and TA):

-

Models TG (rubber/soft tape):

- TG 3: maximum load 50 pieces / maximum volume 40 dm³

- TG 1: maximum load 200 pieces / maximum volume 120 dm³

- TG 2: maximum load 400 pieces / maximum volume 270 dm³

- TG 4: maximum load 800 pieces / maximum volume 560 dm³

- TG 5: maximum load 1000 pieces / maximum volume 720 dm³

-

Models TA (metal tape):

- TA 8: maximum load 1000 pieces / maximum volume 280 dm³

- TA 16: maximum load 1600 pieces / maximum volume 600 dm³

- TA 20: maximum load 2000 pieces / maximum volume 680 dm³

- TA 30: maximum load 3000 pieces / maximum volume 1180 dm³

Options and Customization:

- Selection of tape material (rubber or metal) based on required geometry, weight, and finish.

- Integration of automatic loading/unloading systems and part transport.

- Custom configurations to optimize cycle times and minimize handling.

Why choose this type of shot blasting machine:

- Designed for demanding industrial processes with focus on productivity and reliability.

- Easy integration into production lines and adaptability for different batch sizes and part dimensions.

- Manufacturer-backed spare parts inventory, reducing downtime.

For detailed technical specifications, energy consumption, dimensions, and automation options, request the appropriate technical datasheet or a personalized quote.

Product Details

Harmonized commodity

Brand:

COGEIM

Country of origin:

Italy

Industrial sector:

Model:

TG / TA (TG3, TG1, TG2, TG4, TG5; TA8, TA16, TA20, TA30)