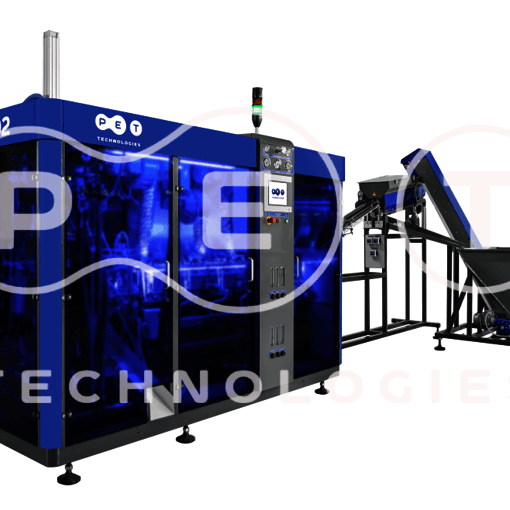

A semi-automatic stretch blow-moulding machine engineered to produce PET bottles for small-to-medium production runs. The UPF-5 delivers consistent bottle quality and stable output while reducing capital and operating complexity compared with fully automatic lines.

Key features

- Machine type: Semi-automatic stretch blow moulding for PET bottles

- Model: UPF-5

- Supported bottle volumes: 0.2–3.0 L and 5.0–6.0 L

- Typical production capacity:

- 0.2–3.0 L bottles: 600–800 bottles/hour

- 5.0–6.0 L bottles: 300–350 bottles/hour

- Designed for PET applications commonly found in beverage, edible oil, household chemicals and similar liquid packaging

- Semi-automatic operation: lower capital cost and simpler line integration than fully automatic systems; suitable where some manual loading/unloading or supervision is acceptable

Benefits for B2B buyers

- Cost-effective solution for companies needing reliable PET bottle production without the complexity of full automation

- Scalable for small-to-medium volume production and pilot or niche product lines

- Consistent part quality appropriate for consumer packaging

Notes

- Moulds, tooling and line peripherals (preform ovens, conveyors, automation upgrades) are typically supplied separately—specify required bottle geometry and preform type when requesting options or a quotation.

- For full technical details (power requirements, compressed air consumption, cycle parameters, machine footprint and installation requirements), request the machine datasheet or technical specification from the supplier.

Product Details

Harmonized commodity

Country of origin:

Austria

Industrial sector:

Model:

UPF-5