-

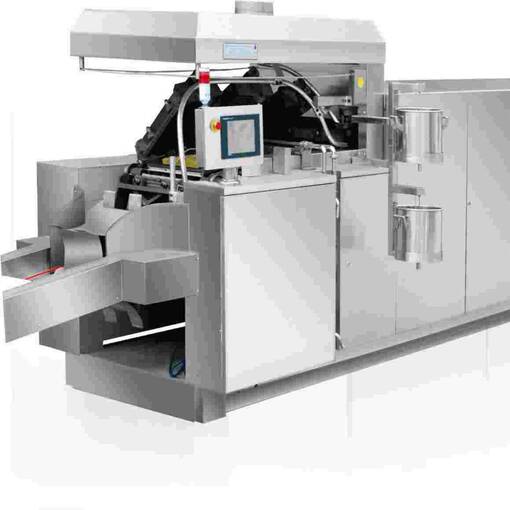

Continuous tunnel-type washing line designed for the treatment, cleaning, and automatic degreasing of small and medium-sized parts in industrial processes.

-

Entire construction in stainless steel with modular design featuring multiple configurable phases according to the process: pre-washing, washing, rinsing, passivation, phosphatization, and drying. Each tunnel is custom-made to adapt to process requirements, chemical composition, and production rates.

-

Transport via flat metal belt with input and output openings for integration with automatic loading systems (conveyor belts, feeders, or robots). Ideal for repetitive operations requiring high uniformity and control of treatment times.

-

Operational and environmental advantages:

- Reduction of manual handling and increased productivity through continuous treatment.

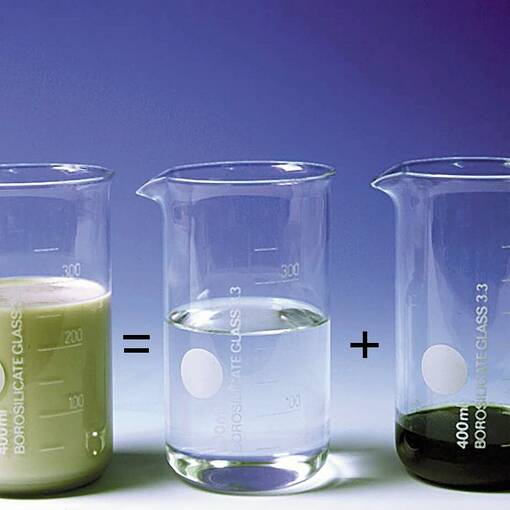

- Use of alkaline solutions and closed circuits that optimize chemical consumption and wastewater.

- Ease of maintenance thanks to corrosion-resistant industrial materials and components.

-

Standard models (example configurations):

- G200: belt width 200 mm, length 3000 mm, volume 300 liters.

- G300: belt width 300 mm, length 3000 mm, volume 300 liters.

- G400: belt width 400 mm, length 3000 mm, volume 300 liters.

- G500: belt width 500 mm, length 3000 mm, volume 500 liters.

- G600: belt width 600 mm, length 3000 mm, volume 500 liters.

- G700: belt width 700 mm, length 3000 mm, volume 500 liters.

-

Typical applications: cleaning and degreasing of metal parts and mechanical components in automotive industries, component manufacturing, turning/milling, surface treatment, and industrial maintenance workshops.

-

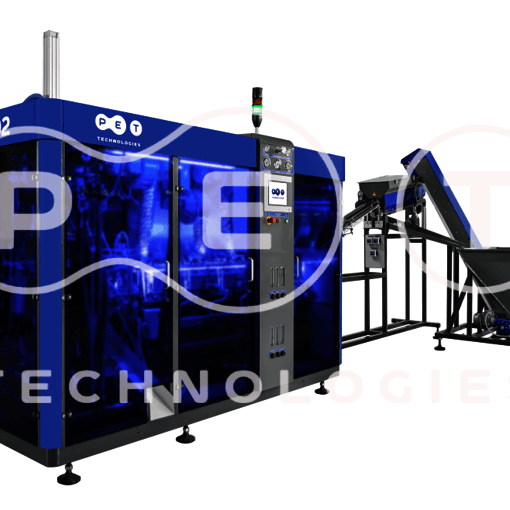

Customization: modular design to adapt stages, immersion times, temperature, recirculation management, and compatibility with specific chemical processes. It is recommended to consult process specifications (type of parts, production rate, treatment requirements, and tank volume) to size the solution.

If you need a customized proposal with technical data (consumption, power, installation requirements, and automation options), provide the dimensions and piece flow rate per minute or per hour.