Vacuum magnetron sputtering metal deposition equipment designed for PVD deposition of metallic films on various substrates. This is an updated sputtering technique that combines high deposition speed, lower process temperature, stable behavior, and simple handling, suitable for industrial production and R&D processes.

Main features:

- Deposits metallic films, iridescent films, and gold coatings via evaporation/sputtering.

- Compatible with metals and substrates such as treated glass, plastics, mica, and ceramics.

- Enables the use of different targets and reactive gases to achieve a wide variety of functional and decorative films.

- Vacuum chamber process that reduces contamination and improves coating uniformity.

Advantages for companies:

- Increased productivity due to higher sputtering speeds compared to conventional processes.

- Lower substrate heating, expanding coating possibilities for heat-sensitive materials.

- Simplified process operation and control for more reproducible production.

- Configurable according to objectives: target changes, reactive gas options, and process parameters based on the application.

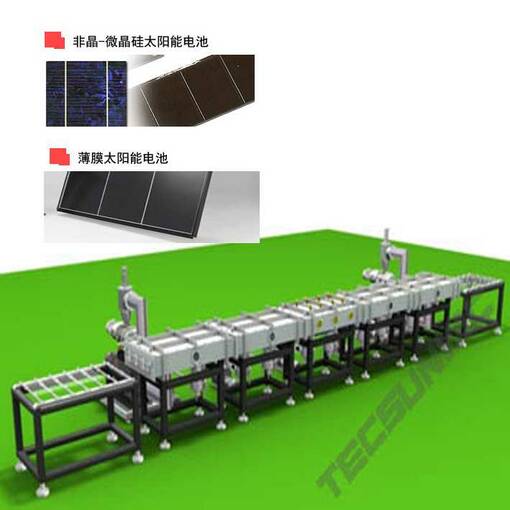

Typical applications:

- Decorative and reflective metalization on glass and plastics.

- Functional coatings on ceramic and mica components.

- Production of thin films for prototypes and industrial batches.

For quotes and technical specifications (performance, chamber size, number of magnetron sources, energy consumption, and automation), consult the available configuration options based on your application and production volume.

Product Details

Country of origin:

China

Industrial sector: