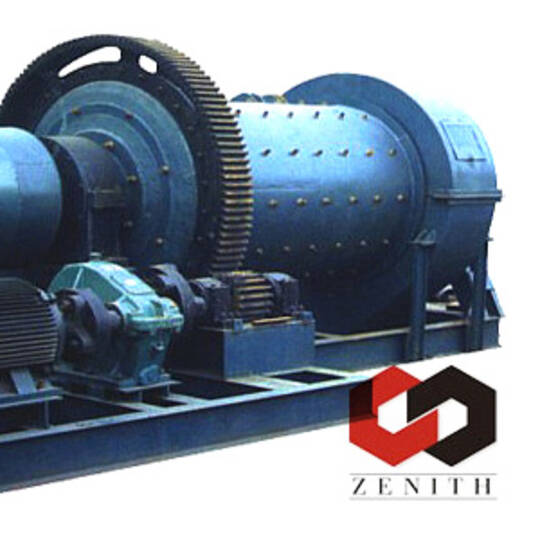

Ball mill designed for secondary processing after crushing: the material, once crushed, passes through this mill to achieve the required particle size. It is a fundamental equipment in grinding circuits in construction materials, mining, and chemical industries plants.

Main applications:

- Suitable for dry or wet grinding of various types of minerals and industrial materials.

- Commonly used in: cement, silicate products, new construction materials, refractory materials, fertilizers, metals (ferrous and non-ferrous), ceramics and glass.

Operating modes:

- Dry grinding: recommended for refractory materials, cement, and fertilizer production.

- Wet grinding: suitable for minerals, ceramic and industrial raw materials where wet suspension or classification is required.

Features and advantages for industrial use:

- Stable operation and wear-resistant design, suitable for continuous operation.

- Uniform particle size of the final product, advantageous for circuit grinding processes.

- Low investment cost relative to performance; focus on energy saving during operation.

- Simple operation and integrated safety measures for use in plants.

Integration considerations:

- Ideal as a secondary stage in crushing and grinding lines; can be integrated with feeders, classifiers and separation systems.

- Recommended to evaluate process parameters (capacity, reduction index, desired final size, moisture) to select the optimal mill configuration.

If you need technical specifications (capacity, dimensions, lining type or grinding media) consult your process requirements to determine the most appropriate version.

Product Details

Country of origin:

China

Industrial sector: