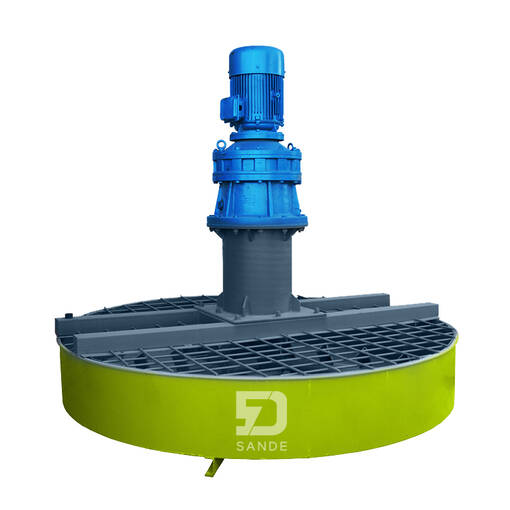

A heavy-duty vertical crusher engineered for bio-organic fertilizer and compost production. Designed by integrating proven domestic and international crushing technologies, this vertical grinder pulverizes high-moisture organic feedstocks and municipal solid waste components to particle sizes that meet granulation requirements, while reducing equipment counts and overall process length.

Key benefits

- Accepts high-moisture fermented organic materials (moisture content typically 25–50%) without blocking or loss of performance.

- Reduces downstream equipment investment and operating cost by combining crushing and size-preparation in a single, compact stage.

- Produces adjustable pulverized particle sizes to match granulation or composting specifications.

- Capable of processing hard contaminants commonly found in MSW streams — glass, ceramics, bricks and gravel — allowing safer, more consistent application of the finished product.

- Engineered for robust continuous operation in industrial fertilizer and waste-processing environments.

Features

- Vertical configuration that shortens production flow and saves floor space compared with multi-stage systems.

- Adjustable grinding settings to tailor particle size for different granulation or composting lines.

- Built for heavy-duty materials handling; wear-resistant components and serviceable access points simplify maintenance.

Typical applications

- Bio-organic fertilizer manufacturing and compost preparation lines

- Municipal solid waste pre-processing (organic fraction reclamation)

- Industrial and agricultural material recycling centers

- Plants requiring feedstock size reduction ahead of granulation or further biological treatment

Buying considerations

- Specify required throughput (t/h), desired finished particle size range, and inlet material moisture to receive a suitable technical proposal.

- Integration with upstream fermentation/pretreatment and downstream granulation or drying equipment is common — ask for interface dimensions and electrical requirements when ordering.

For commercial quotes or engineering datasheets, provide process capacity, typical feed composition, and expected line layout so suppliers can match machine configuration and wear-package to your application.

Product Details

Brand:

Sande Machinery

Country of origin:

China

Industrial sector:

Model:

SDFLF-800