A heavy-duty industrial dryer engineered for continuous drying of high-moisture mineral and organic materials. Designed to handle large throughput with stable, low-energy operation, this dryer is suited for plants that need reliable moisture reduction for downstream processing, transport or storage.

Key features

- High capacity: built for large daily throughput in continuous production lines.

- Energy-efficient operation: optimized heat transfer and process control to reduce fuel/electricity use.

- Stable, low-maintenance design: rugged construction and straightforward internals reduce downtime and service costs.

- Easy operation and control: user-friendly controls for consistent drying performance and simple operator training.

- Versatile material compatibility: suitable for a broad range of viscous, granular or paste-like feedstocks.

Typical applications

- Organic fertilizer production

- Metallurgical slag processing (steel-plant slag)

- Mining and mineral processing (clay, limestone, phosphogypsum)

- Power plant byproducts (fly ash, slime)

- Sewage and wastewater treatment sludge

Benefits for buyers

- Improves product stability and handling by reducing moisture to specification

- Lowers logistics costs through reduced weight and easier storage

- Integrates into existing production lines with minimal footprint changes

- Reduces overall processing costs thanks to efficient energy use and high output

Model reference

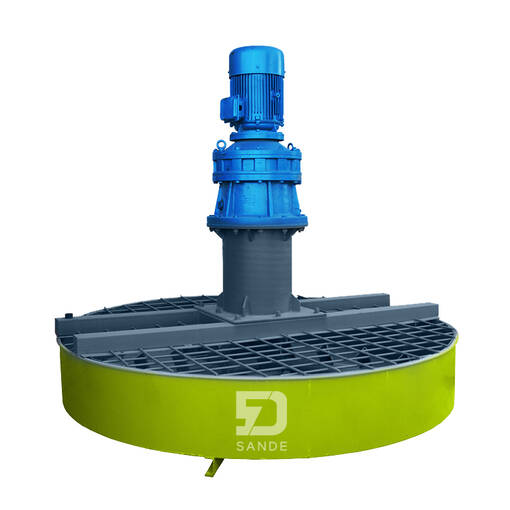

Model: SDHG-1010

For project quotes, include required capacity (t/h or kg/h), inlet moisture and target outlet moisture so the system can be sized and configured to your process requirements.

Product Details

Harmonized commodity

Brand:

Sande Machinery

Country of origin:

China

Industrial sector:

Model:

SDHG-1010