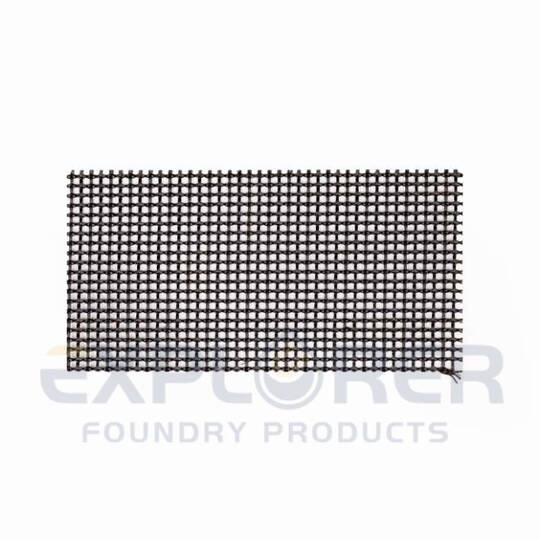

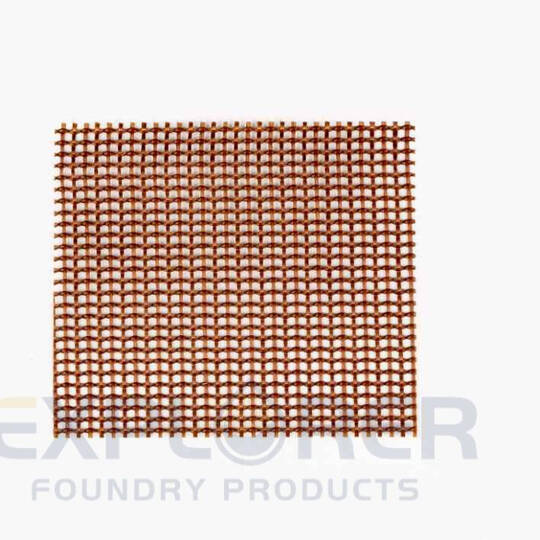

High-performance fiberglass mesh sheets engineered for molten-metal filtration in foundry and casting operations. Constructed from inert glass-fiber materials, these filter sheets deliver reliable filtration performance under the elevated temperatures typical of aluminum and other non‑ferrous metal casting processes.

Key features

- High-temperature resistance: Glass-fiber construction maintains structural integrity and filtration properties in demanding thermal environments.

- Effective inclusion removal: Three-dimensional mesh structure captures non-metallic inclusions, slag and other contaminants to improve metal cleanliness and final part quality.

- Chemical stability: Inert material prevents reactions with molten metal, helping preserve metallurgical properties of the cast alloy.

- Low pressure drop and high permeability: Open-pore design allows smooth metal flow with minimal resistance, supporting steady casting rates and efficient energy use.

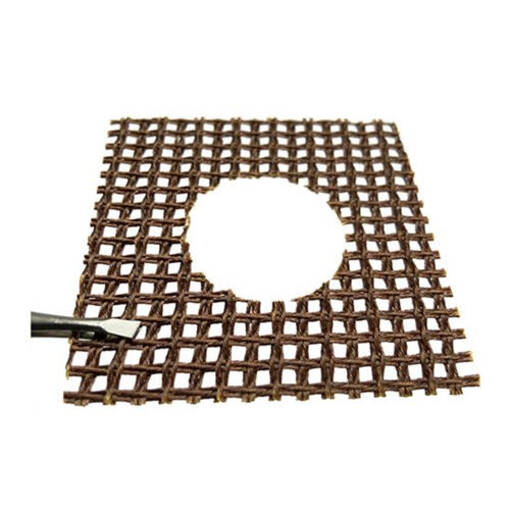

- Customizable form factors: Sheets can be supplied and cut into a variety of shapes — round, square, fan-shaped and other profiles — to integrate seamlessly with different mold and filter housings.

Benefits for foundry operations

- Improves yield and reduces scrap by trapping inclusions before they reach the mold cavity.

- Enhances surface finish and mechanical integrity of cast components, lowering downstream rework and inspection costs.

- Supports consistent metal flow and temperature control thanks to balanced porosity and permeability.

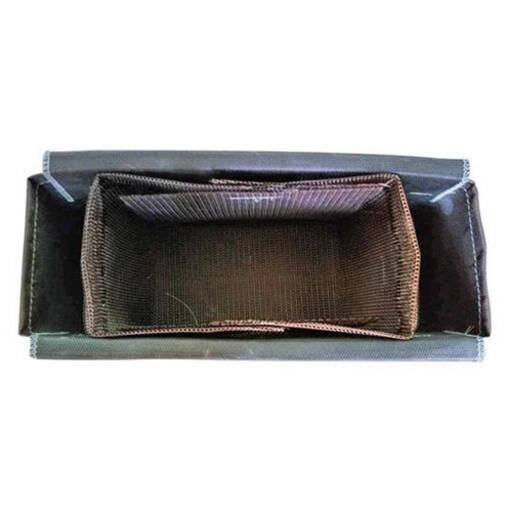

- Adaptable to a wide range of casting setups — from simple gravity pours to more complex gating systems.

Typical applications

- Aluminum casting and filtration for automotive components (wheel hubs, engine parts, transmission housings)

- Aerospace and high-performance alloy castings where inclusion control is critical

- General non‑ferrous foundry operations and alloy production where improved metal cleanliness is required

Ordering and specification notes

- Sheets are available for use as stand-alone filters or for conversion into pre-cut filter elements to fit specific mold designs.

- Specify required shape, thickness, and desired filtration grade/porosity when ordering to ensure compatibility with your casting process.

- Follow standard foundry installation and handling practices for filter placement and preheating (if applicable) to maximize filter life and performance.

If you need detailed technical data (porosity, thickness options, recommended operating procedures) or custom cutting services, provide your casting parameters and required filter geometry so suppliers can propose appropriate grades and formats.

Product Details

Harmonized commodity

Country of origin:

China

Industrial sector: