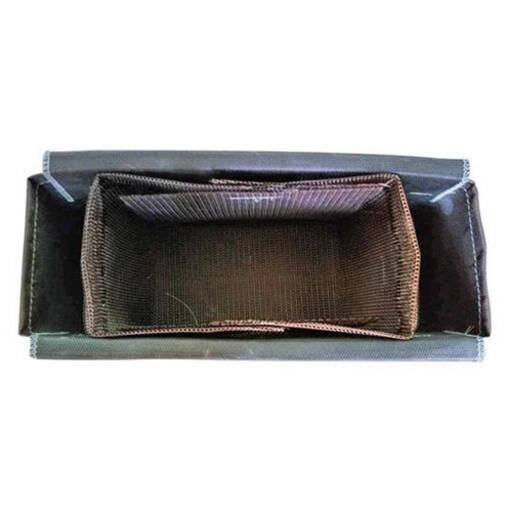

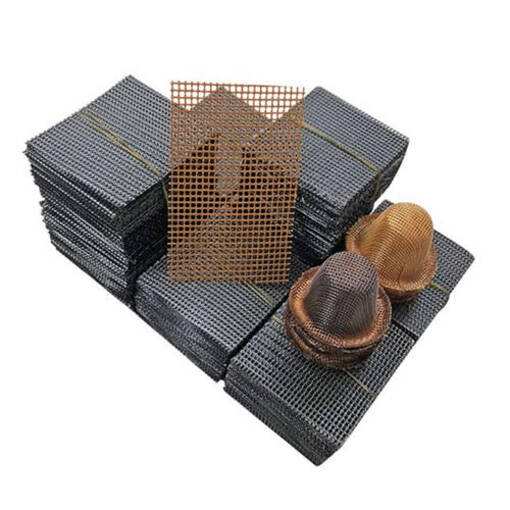

High-performance glass-fiber bag filters engineered for molten aluminum filtration in foundry and casting operations. Constructed from glass-fiber filter media, these bag-style elements capture non-metallic inclusions and dross from liquid aluminum to deliver cleaner metal, more uniform grain structure and fewer internal and surface defects.

Key benefits:

- Effective removal of non-metallic inclusions and slag to improve melt cleanliness and casting quality

- Reduces porosity, cold shuts and other casting defects, increasing yield and decreasing rework

- Promotes more uniform grain structure and consistent downstream processing (rolling, extrusion, machining)

- Suitable for ingot casting, strip/belt continuous casting and precision aluminum castings

- Applicable across a wide range of aluminum alloys used in aerospace, automotive and electronics components

- Rugged glass-fiber construction provides good thermal and chemical stability for molten-metal filtration

Product and supply notes:

- Bag-style filter elements are supplied in multiple sizes and porosities to match different filtration housings and casting processes

- Can be integrated into standard molten-metal filter holders or bespoke filter systems used in foundries

- Custom dimensions and media specifications available on request to meet specific alloy, flow-rate and cleanliness targets

These glass-fiber bag filters are intended for metallurgical applications where improved metal quality, reduced scrap and consistent product performance are priorities.

Product Details

Harmonized commodity

Country of origin:

China

Industrial sector: