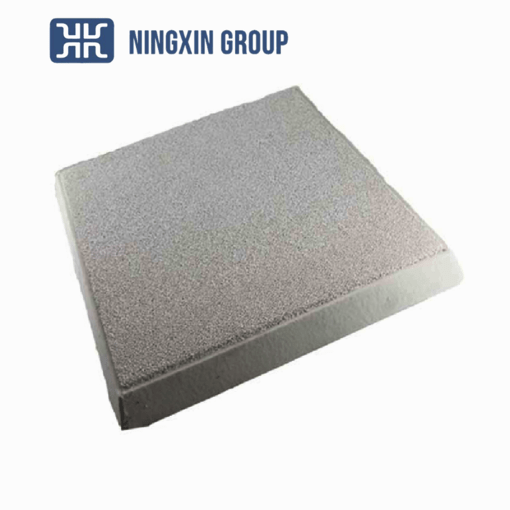

Zirconia ceramic foam filters are high-performance porous refractory elements designed for molten-steel filtration. Engineered for use with unalloyed, low-alloy, stainless and high-alloy steels (service up to 1700°C), these filters remove non-metallic inclusions, promote laminar flow, and help reduce entrapped gas — producing cleaner metal and higher-quality castings with fewer defects and less scrap.

Key benefits

- Excellent chemical and thermal resistance to molten steel and aggressive alloy melts

- Effective capture and retention of inclusions and slag particles

- Promotes laminar flow to reduce turbulence and re-entrainment of impurities

- Helps reduce gas-related defects and improves final casting integrity

- Contributes to lower scrap rates and improved downstream processing yields

Typical applications

- Molten steel filtration in foundries and steel plants

- Use in refining and casting operations where high-alloy or stainless steels are processed

- Suitable for processes demanding high cleanliness and low inclusion levels

- Also employed as catalyst carrier media in air treatment applications where ceramic foam structures are required

Product notes

- Rated for continuous exposure to molten steel temperatures up to approximately 1700°C

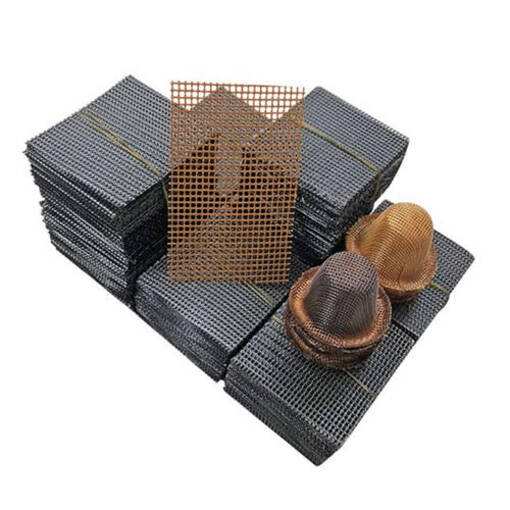

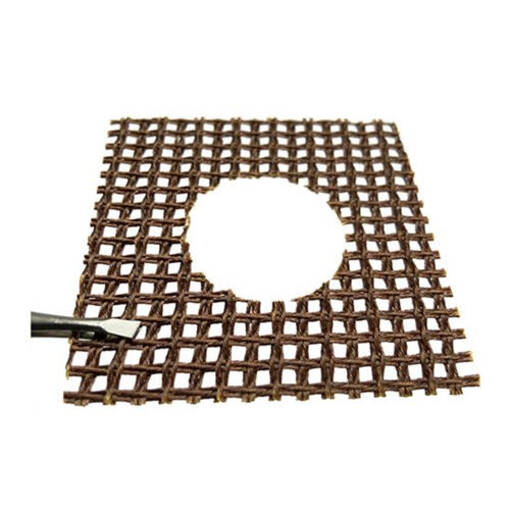

- Supplied in foam block shapes and sizes to fit gating systems or filtration housings; pore structure and nominal porosity vary by grade (select grade based on alloy type and required filtration fineness)

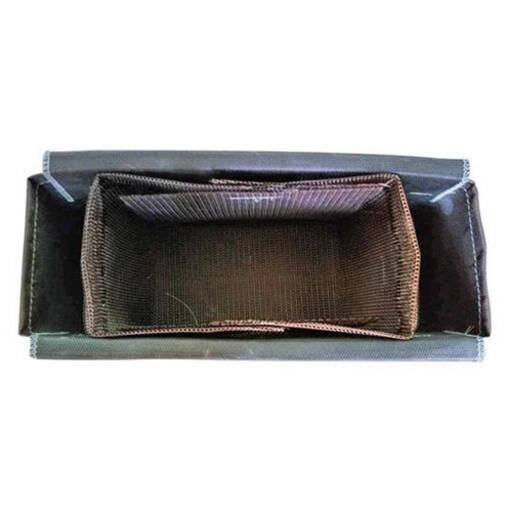

- Integration with existing tundish/ladle/mold filtration systems may require sizing or mounting adaptors

For specification-driven purchases, request detailed grade data (porosity/PPI, mechanical strength, recommended maximum service temperature for specific alloys) and sample testing in representative process conditions.

Product Details

Harmonized commodity

Country of origin:

China

Industrial sector: