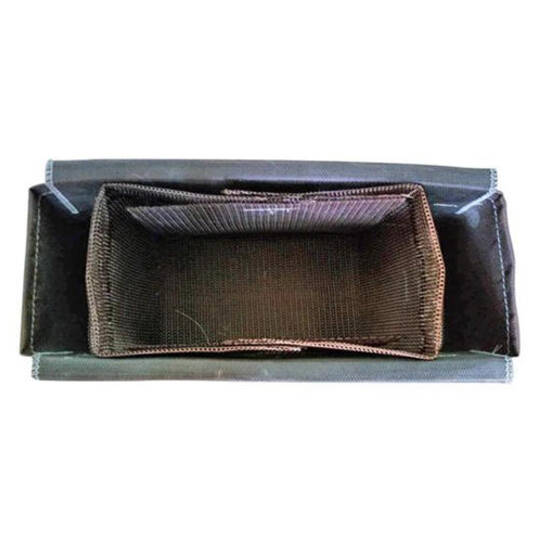

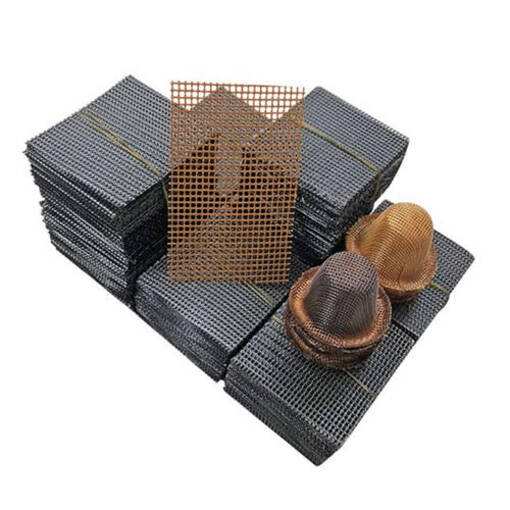

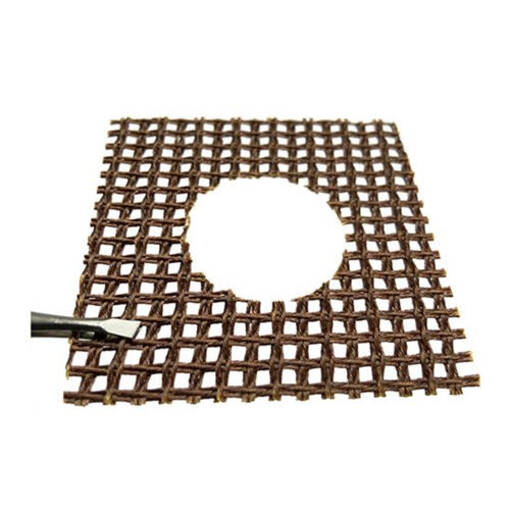

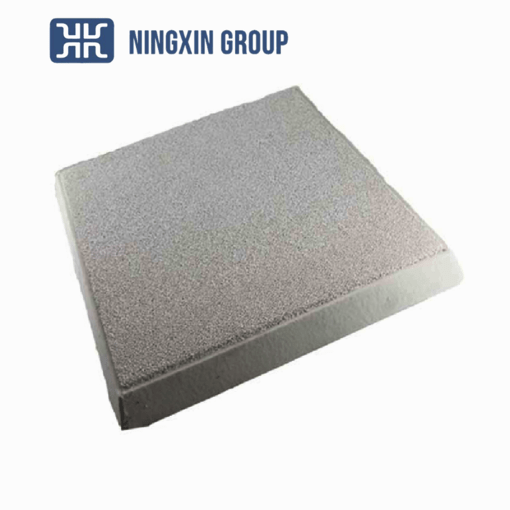

High-temperature E-glass shunt combo bag engineered for molten aluminum filtration and flow distribution. Woven from alkali-free E-glass yarn with a high-twist, high-strength construction and a specialized post-treatment (resin-coated and thermally carbonized) to withstand continuous exposure up to 1000 °C. The design combines effective filtration with controlled flow distribution to reduce turbulence, capture non-metallic inclusions, and minimize air entrainment in castings.

Key benefits:

- Reliable filtration and even distribution of molten aluminum into molds and risers

- Effective for large-diameter ingot and billet pours, rectangular slabs and complex alloy castings

- Compatible with sand casting, permanent mold, shell mold, gravity/die casting and investment casting processes

- Reduces inclusions, turbulence and porosity; improves surface finish and first-pass yield

- Thermally stable (up to 1000 °C) with minimal smoke, fumes or flame during operation—improves foundry working environment

- Constructed for durability under repeated thermal cycling and high-flow conditions

Typical applications:

- Foundries producing aluminum ingots, billets, slabs and precision cast components

- Processes requiring improved temperature distribution and vertical flow control of molten aluminum

- Operations seeking lower scrap rates, fewer defects and reduced downstream rework

Notes:

- Commonly offered as a "shunt combo" or distribution/filter bag (also referred to as fiberglass mesh filter or thermally fused shunt bag). Specifications such as bag dimensions, weave density/mesh size and coating formulation vary by supplier—confirm those parameters to match your melt flow rate, pour geometry and casting type before ordering.

Product Details

Harmonized commodity

Country of origin:

China

Industrial sector: