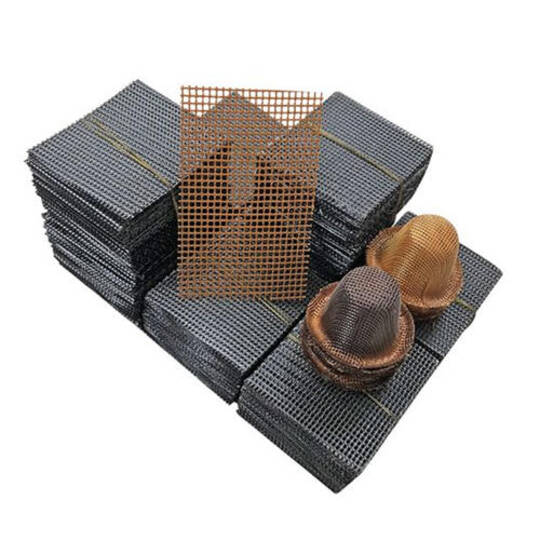

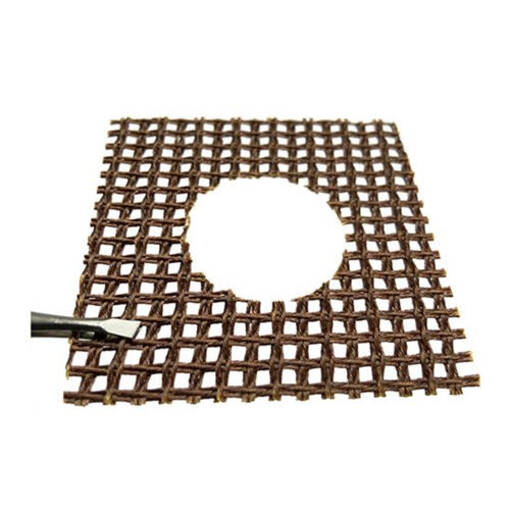

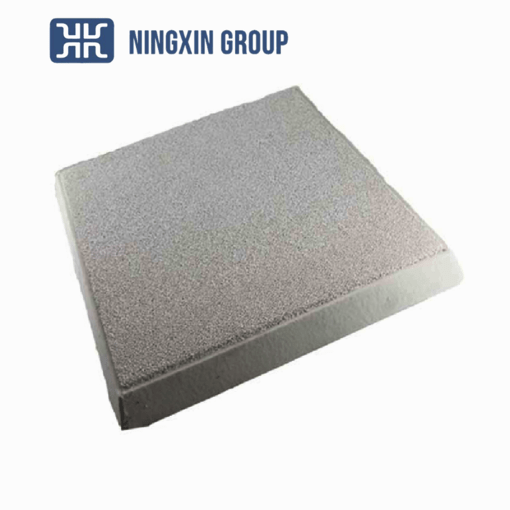

A high-performance fiberglass filtration mesh engineered for aluminum casting applications. Woven from high-twist, high-strength alkali-free fiberglass yarn and finished with a specialized resin and high-temperature carbonizing post-treatment, this mesh withstands molten metal temperatures up to 900°C while remaining smokeless, odorless and flameless throughout the filtration process.

Key features

- Constructed from alkali-free, high-twist/high-strength fiberglass yarn for mechanical durability and dimensional stability

- Special resin coating and high-temperature carbonized post-treatment for enhanced thermal and chemical resistance

- Rated for continuous exposure up to 900°C

- Smokeless, odorless and flameless during filtration — improves workplace conditions and reduces secondary contamination

Primary benefits

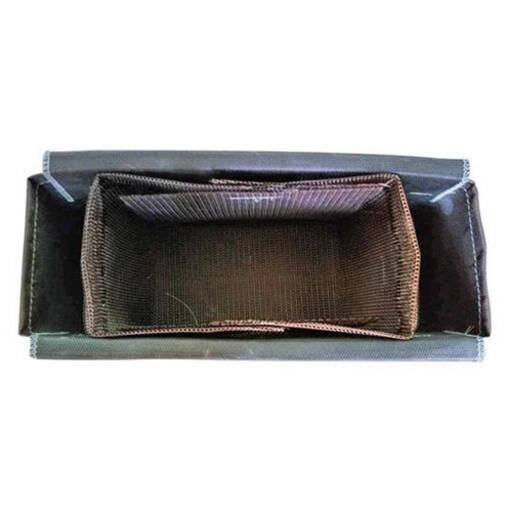

- Effectively captures inclusions and non-metallic impurities, reducing turbulence and entrained gases to improve casting integrity and surface finish

- Helps eliminate air bubbles and porosity, increasing first-pass yield and reducing scrap

- Does not contaminate molten aluminum or alter its chemical composition

- Filter-containing aluminum scrap (from sprues, risers and gating) can be returned directly to the furnace for remelting, lowering material costs

Typical applications

- Precision and gravity casting of aluminum alloys

- Automotive and motorcycle wheels

- Cylinder pistons, rods, ingots and plates

- Any foundry process requiring cleaner aluminum melts and improved casting quality

This fiberglass filter mesh is suited for foundries and alloy processors seeking a durable, high-temperature filtration solution that improves final casting quality while minimizing emissions and rework.

Product Details

Harmonized commodity

Country of origin:

China

Industrial sector: