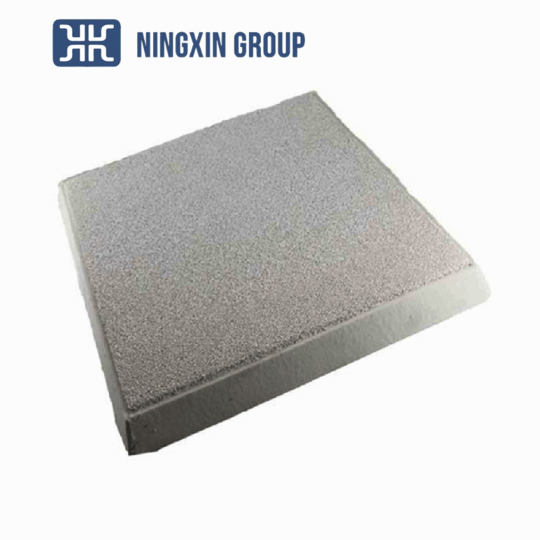

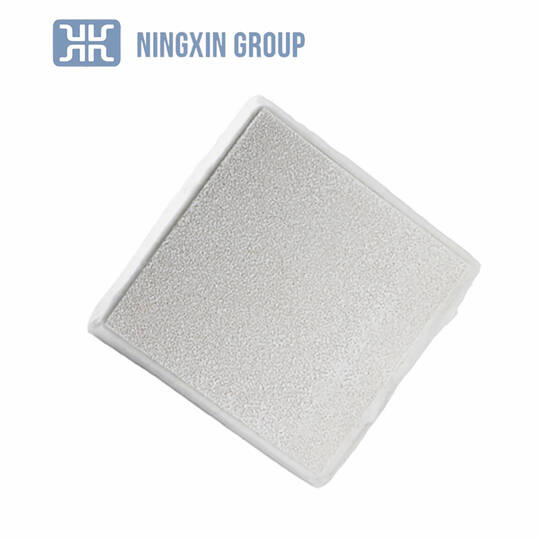

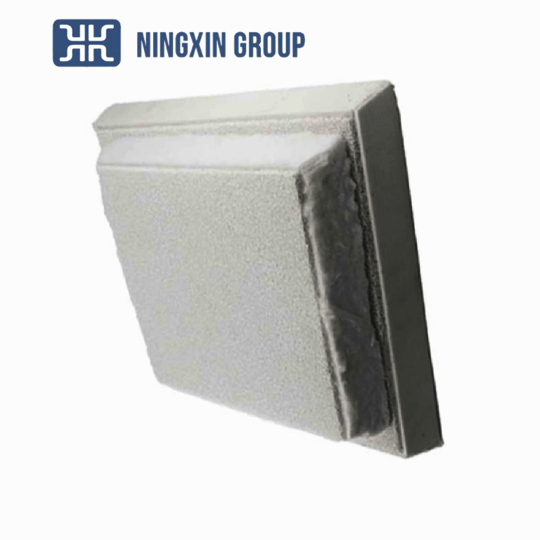

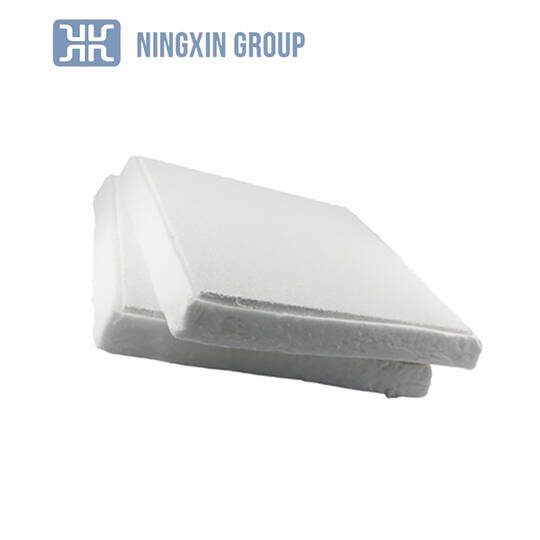

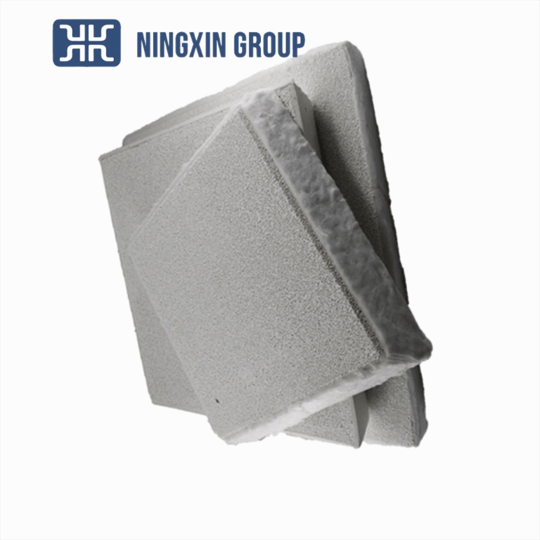

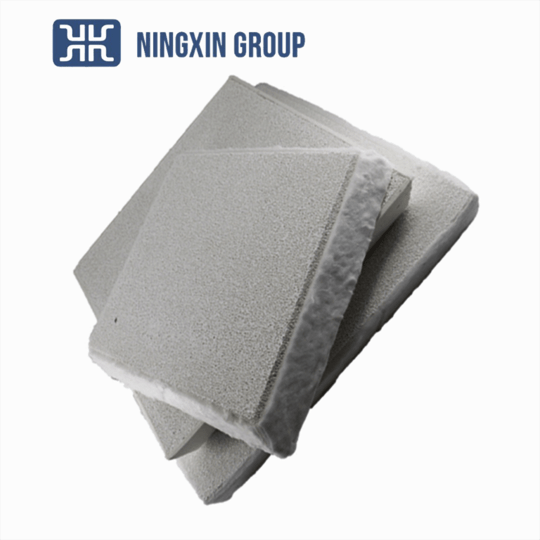

High-performance alumina-based ceramic foam filter engineered for molten aluminum and aluminum-alloy filtration in foundries and cast houses. The open-cell ceramic foam structure provides effective removal of non-metallic inclusions and entrained gases while promoting laminar metal flow to produce cleaner, higher-quality castings with fewer defects.

Key benefits

- Effective inclusion removal and degassing: reduces internal defects and improves mechanical properties of castings.

- Promotes laminar flow: minimizes turbulence and re-entrainment of dross during fill.

- Excellent resistance to chemical attack by molten aluminum: durable in typical casting environments.

- Reduces scrap and rework: fewer inclusion-related rejects lower production costs.

- Increases process flexibility and productivity: easier alloy changes and potential for faster extrusion/rolling and casting cycles.

- “No holding metal”: designed to avoid unnecessary metal retention in the filter.

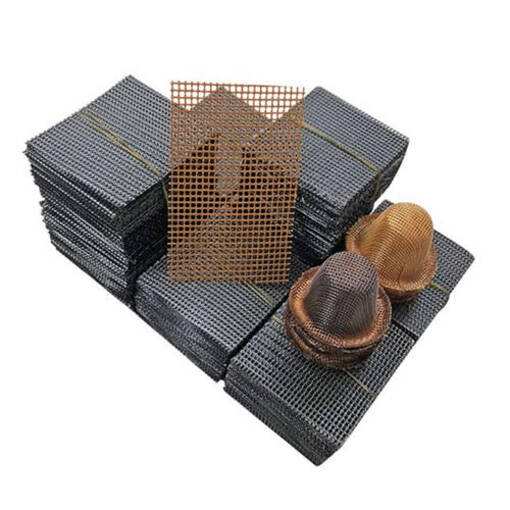

Typical applications

- Filtration of molten aluminum and aluminium alloys in foundries

- Integration into gating systems, ladles, tundishes and casting lines to improve metal cleanliness

Model and identification

- Model: ALU-CFF (NINGXIN-CFF-ALU)

Why choose this filter

This alumina ceramic foam filter is intended for operations that require reliable, repeatable improvement in melt cleanliness and casting yield. By removing inclusions and reducing trapped gas, the filter helps reduce downstream defects, lower scrap rates, and improve overall process efficiency — delivering measurable cost savings in high-volume non-ferrous metal production.