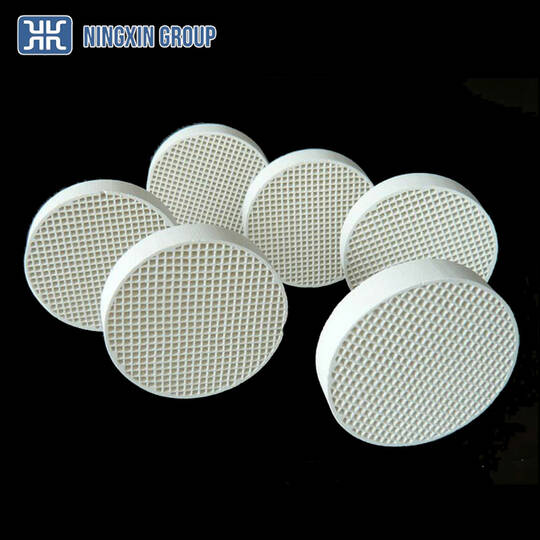

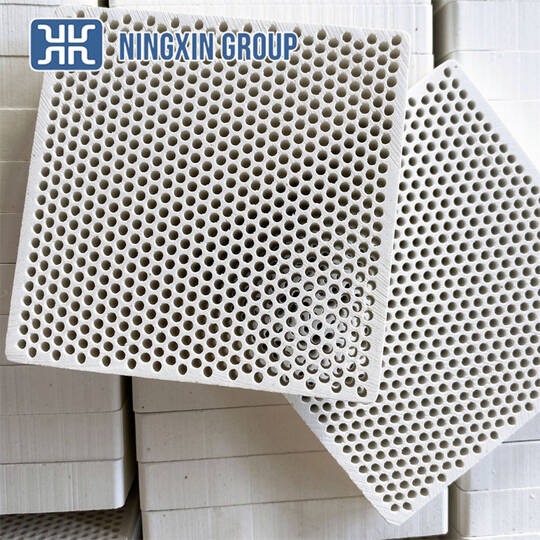

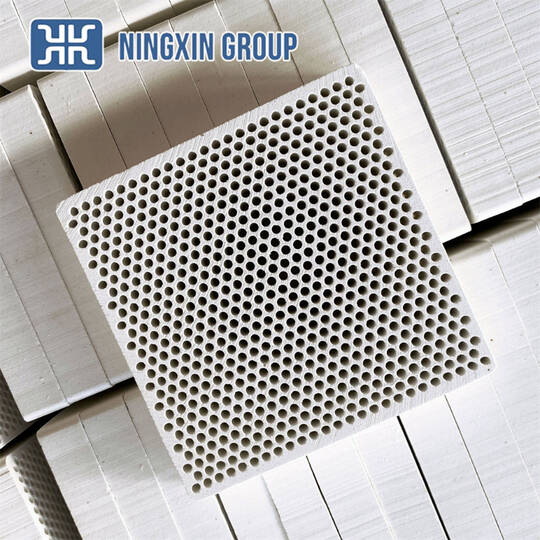

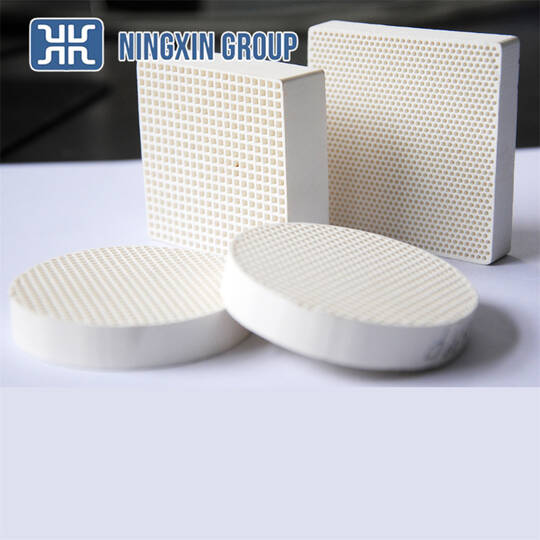

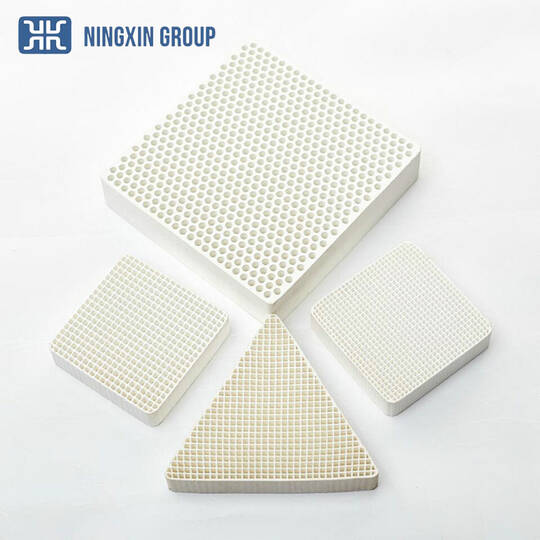

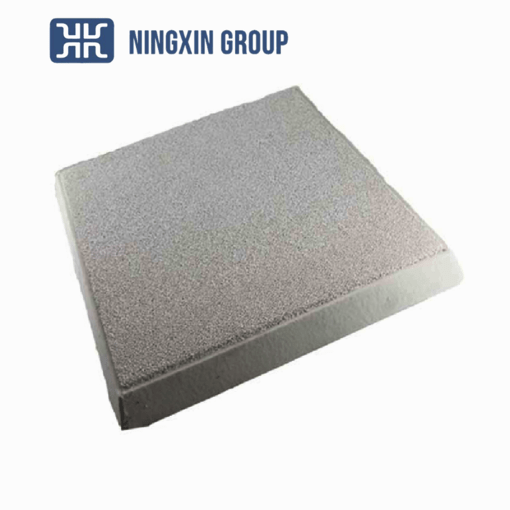

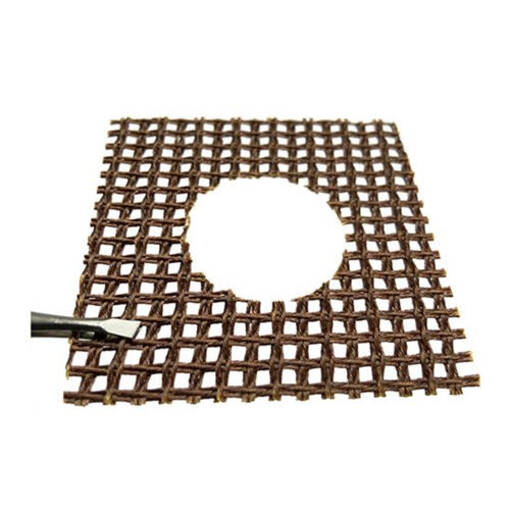

Extruded honeycomb ceramic filters manufactured from mullite-based ceramic for molten-metal filtration. The open-cell, engineered cellular structure captures non-metallic inclusions, reduces turbulence in the flow and provides a controlled balance between filtration flow rate and mechanical strength. The material and design deliver high thermal stability, dimensional accuracy and chemical resistance for demanding ferrous and non‑ferrous casting processes.

Key benefits

- Effective removal of slag and inclusions to improve casting integrity and surface finish

- Engineered cell structure to reduce metal turbulence and promote smooth fill

- High thermal-shock resistance and working temperature tolerance for heavy pours

- Good chemical resistance to acidic and alkaline environments

- Precise dimensions and repeatable performance for automated and manual gating systems

Typical applications

- Filtration of molten iron, steel, aluminum and non-ferrous alloys in foundry casting operations

- Use in gating systems, runners and pour cups where inclusion removal and flow conditioning are required

Technical specifications

- Main material: Mullite (SiO2 based)

- Maximum working temperature: ≤ 1520 °C

- Color: White

- Cell density (CSI): 50 / 100 / 200 / 300 cells per sq. inch

- Porosity: 35–60%

- Compressive strength (room temperature): ≥ 20 MPa

- Bulk density: 0.8–1.2 g/cm³

- Thermal shock resistance: ≥ 2 cycles (1100 °C → room temp)

- Dimensions (L/D × W × T): 37–150 × 37–150 × 8–25 mm (size tolerance ±1 mm)

- Shapes available: round, square, rectangular

Ordering notes

- Specify required cell density (CSI), exact dimensions and shape when ordering

- Typical buyers include foundries and tool shops producing ferrous and non‑ferrous castings

Quality and compatibility

- Designed for high-temperature metal filtration and engineered for repeatable performance in industrial casting environments. Confirm chosen cell density and dimensions against your gating design and metal type for optimal filtration efficiency.

Product Details

Harmonized commodity

Brand:

NINGXIN

Country of origin:

China

Industrial sector:

Model:

NINGXIN-CFF-EXC

Unit type:

Piece

Minimum order (MOQ):

10,000