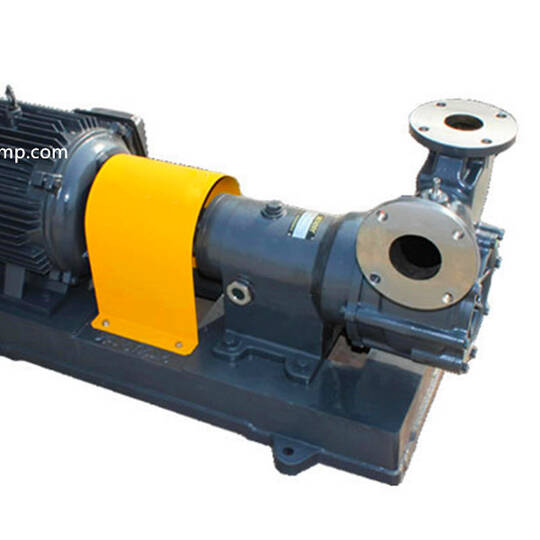

A horizontal, self-priming gas–liquid mixing pump designed to entrain, mix and dissolve gases into liquids and deliver the ready solution directly to the point of use. The pump combines suction, high-speed impeller mixing and pressure dissolution in a single compact unit, eliminating the need for separate compressors, external agitators or large pressurized gas tanks.

Key features

- Self-priming horizontal design with standard quick‑coupling connection for straightforward installation and maintenance.

- All wetted flow parts constructed from stainless steel for corrosion resistance and sanitary service.

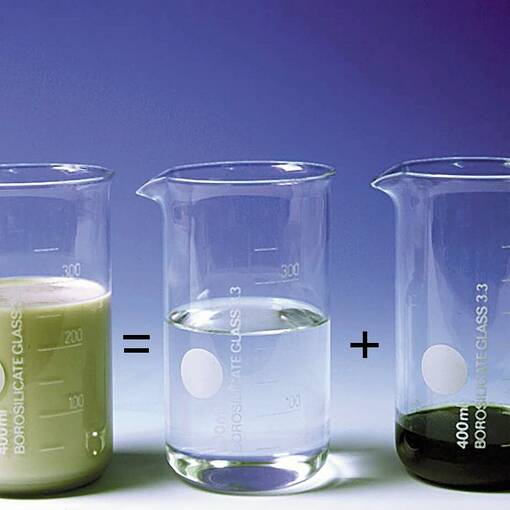

- High-speed rotating impeller uses negative pressure at the suction port to draw in gas; gas and liquid are intensively mixed and dissolved inside the pump.

- Typical gas–liquid dissolution efficiency: 80–100%, reducing or removing the need for reaction towers or large pressure vessels.

- Capable of attracting, mixing, dissolving and delivering the treated liquid in a single stage, simplifying plant layout and lowering capital and operating costs.

Typical applications

- Dissolved-oxygen and ozone generation systems (oxygen-rich water, ozone water).

- Dissolved-gas feed for flotation and biochemical treatment equipment.

- Circulation, transfer and pressurization in temperature-regulating systems and filtration lines.

- Extraction and transfer of low-viscosity liquids from storage tanks and underground tanks.

- Spray and dosing of clean water, pure water, food-grade and chemical liquids; handling of foaming liquids and long horizontal pipelines.

- Situations requiring intermittent operation or where water hammer and rapid back-pressure changes occur.

Operating parameters and compatibility

- Suitable fluids: thin, clean, low-viscosity liquids (acid/alkaline compatibility within pH 3–9).

- Liquid temperature range: -15°C to 120°C.

- Maximum ambient temperature: +40°C.

- Typical gas:liquid volume ratio at suction ~1:9 (inspiratory gas volume ≈ 8–10%).

- Required NPSH (suction lift / imbibition height): approx. 9 m (as specified).

Benefits for industrial users

- Reduces footprint by combining gas suction, mixing and delivery in one unit.

- Lowers initial capital expenditure and ongoing costs by removing separate compressors, mixers and large gas storage.

- Simplifies piping and controls; easy integration into existing circulation or dosing loops.

- Stainless steel wetted path improves durability and suitability for sanitary or corrosive environments (within specified pH/temperature limits).

Installation & maintenance notes

- Install horizontally with standard quick-coupling connections; ensure suction conditions meet the required NPSH and that entrained gas percentage remains within the specified range.

- Use for clean, low‑viscosity fluids; avoid solids-laden or highly viscous media unless specified by vendor.

- Regular inspection of impeller and seals recommended to maintain dissolution efficiency and service life.

For specification matching, provide expected flow, head, motor rating and process gas type when requesting technical data or a quotation so a model can be sized to your application.

Product Details

Harmonized commodity

Brand:

kenshine-pump

Country of origin:

China

Industrial sector:

SKU:

SET

GTIN/EAN:

841370

MPN:

QYB

Model:

QYB

Unit type:

Set

Minimum order (MOQ):

1