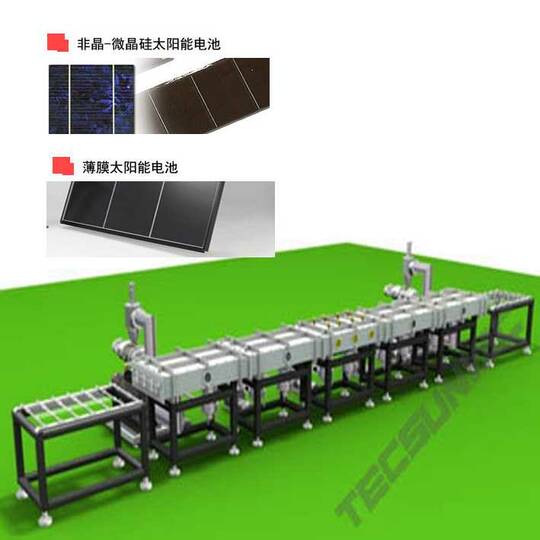

Industrial line for the manufacturing of amorphous silicon photovoltaic cells designed for large-format glass substrate panel production at scale. The process integrates key stages of a thin-film production line: glass preparation and transportation, CVD/PVD metallization to deposit transparent conductive layers, amorphous silicon layer deposition via PECVD, cathodic sputtering for aluminum or AZO films, laser scribing (laser tracing), and subsequent verification, analysis, and packaging of cellular components.

Main Features

- Integrated processes: CVD/PVD for metallization, PECVD for a-Si layers, sputtering for metals and conductive oxides, and laser processing for interconnection and patterning.

- Designed for large-format glass substrates and thin-film module manufacturing.

- Complete workflow: from glass handling and cleaning to inspection, quality testing, and final packaging.

- Modular and scalable design: allows adaptation to varying production capacities and automation levels according to plant requirements.

Advantages for Manufacturers

- Simpler process and higher silicon material utilization compared to crystalline silicon cells, with potential production cost reduction.

- Suitable for continuous production and industrial batches, as well as installation in thin-film photovoltaic module manufacturing plants.

- Integration of in-line quality control and traceability to optimize performance and reduce rejections.

Recommended Applications

- Manufacturing of amorphous silicon photovoltaic modules and other thin-film devices.

- Pilot lines or capacity expansion in existing plants requiring integrated PECVD/PVD and sputtering processes.

Available Options and Services (depending on supplier)

- Modular and customizable configuration (capacity, automation, substrate size).

- Integration of control systems, optical inspection, and in-line electrical testing.

- Installation, commissioning, and operational training services (consult the supplier for scope and availability).

For exact technical specifications (performance, energy consumption, footprint, hourly output, and automation options), request the product datasheet and process flow diagram from the supplier.