Vacuum metallization PVD equipment manufactured in Guangdong (China), designed to deposit metallic and dielectric coatings on substrates for industrial and optoelectronic applications. These systems combine processes such as magnetron sputtering, electron beam evaporation, and plasma arc PVD to provide uniform, adherent, and reproducible coatings.

Main features and advantages:

- Industrial quality with competitive prices and ISO 9000 certification compliance.

- Wide range of configurations: from individual machines to integrated and automated production lines.

- Agile after-sales service, technical support, and possibility of adapting equipment to specific production requirements.

- Available components: vacuum pumps (rotary and diffusion) and auxiliary systems to ensure stable process conditions.

Available lines and models (summary):

- Magnetron sputtering metallizers (various models and configurations).

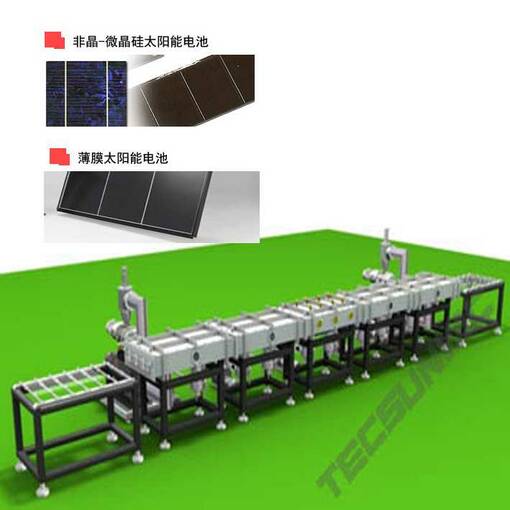

- Sputtering lines for amorphous silicon photovoltaic cells.

- Multifunctional electron beam (e-beam) optical metallizers.

- Plasma arc (plasma-arc) PVD metallizers for specific applications.

- Sputtering lines for low-emissivity (low-e) glass.

- Wire feeding/magnetron metallizers for continuous film processing.

- Magnetron deposition lines for ITO coating on glass.

- Horizontal configuration e-beam optical metallizers.

- Vacuum pumps: rotary pumps, diffusion pumps, and associated accessories.

- Thermal evaporation or electron beam metallizers for various metals and alloys.

Typical applications:

- Photovoltaic industry (contact and functional layer coatings).

- Architectural and low-emissivity (low-e, ITO) glass.

- Optics and photonics (mirrors, filters, antireflective/reflective coatings).

- Electronics and transparent conductive components.

- Decorative and functional coatings for automotive and packaging applications.

Associated services:

- Engineering and customization of lines according to production specifications.

- Installation, commissioning, and operator training.

- Supply of spare parts and preventive/corrective maintenance.

If you need a specific configuration (bandwidth, substrate type, deposition rate, or automation), the manufacturer offers solutions adapted to industrial processes and varying production volumes.

Product Details

Harmonized commodity

Industrial sector: