DIN 42CrMo4 (steel number 1.7225) is a chromium–molybdenum low-alloy engineering steel offered in quenched & tempered and annealed conditions. It combines high tensile strength, good toughness and wear resistance with reliable hardenability, making it suitable for heavy-duty mechanical parts and downhole/oil & gas applications where strength and fatigue resistance are required.

Key attributes

- Alloy system: Cr–Mo low-alloy steel (DIN designation 42CrMo4 / EN 1.7225)

- Typical properties: high strength, good hardenability and toughness, suitable for heat treatment (quench & temper), moderate weldability

- Comparable grades: often referenced alongside AISI 4130 / AISI 4140 family steels for similar mechanical performance

Supply forms and processing options

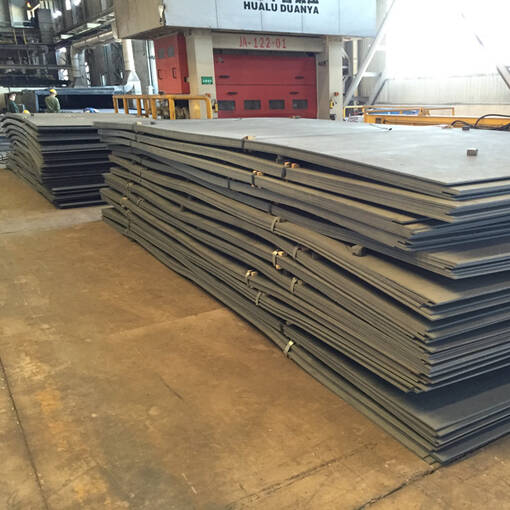

- Stock forms: round bar, flat bar, plate, hexagon and square bar

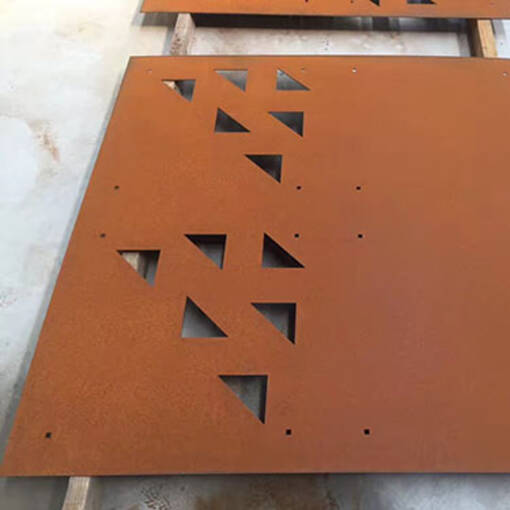

- Secondary processing: cut-to-length (sawing), precision grinding (ground bars), machining and rectangular sawn pieces from plate or flat bar

- Heat treatments: supplied annealed or quenched & tempered (oil quenched available); final heat-treatment and hardness to customer specification

Typical applications

Shafts, axles, gears, couplings, fasteners, hydraulic components, forging billets and components used in oil & gas, heavy machinery and general engineering where a combination of strength and toughness is required.

Ordering guidance

When requesting a quote, please specify required form (bar, plate, etc.), dimensions (diameter/width/thickness and lengths), required heat treatment or delivered condition, surface finish (e.g., ground), quantity, and any certification requirements (material certificates, test reports). This allows accurate lead time and pricing for tailored supply.