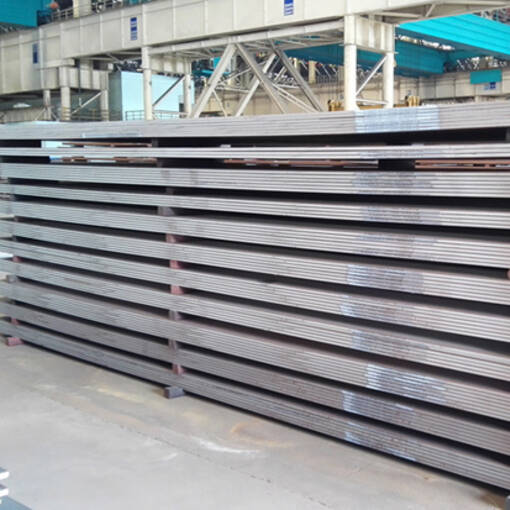

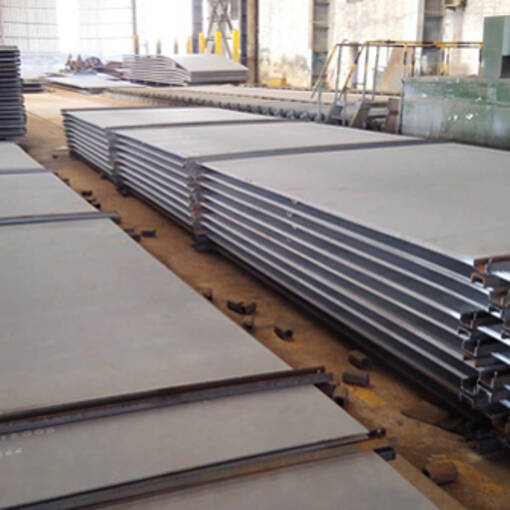

High-quality EN 10083-3 25CrMo4 alloy steel, supplied in plate, sheet, round bar and flat sections. Material is delivered rolled and available in a range of heat-treatment conditions including soft-annealed, normalized, and quenched & tempered to meet different fabrication and performance requirements.

Engineered for components that require elevated-temperature strength, toughness and resistance to high-temperature fatigue and thermal shock. 25CrMo4 is suitable for further heat treatment and machining, and is commonly used where a combination of good mechanical properties and reliable performance under cyclic or shock loading is required.

Typical B2B applications

- Automotive and aerospace components such as axles and axle journals

- Turbine parts and rotors

- Parts subjected to high temperature or cyclic loading where toughness and fatigue resistance are critical

Key selling points

- Conforms to EN 10083-3 specification

- Multiple supply forms: plate, sheet, round bar, flats

- Available in common commercial heat-treatment conditions (soft-annealed, normalized, quenched & tempered)

- Suitable for further machining, forging and heat treatment processes

For commercial enquiries, specify required shape, dimensions, heat-treatment condition and any certification (e.g. EN test reports, material traceability) so suppliers can provide current stock, lead times and pricing.