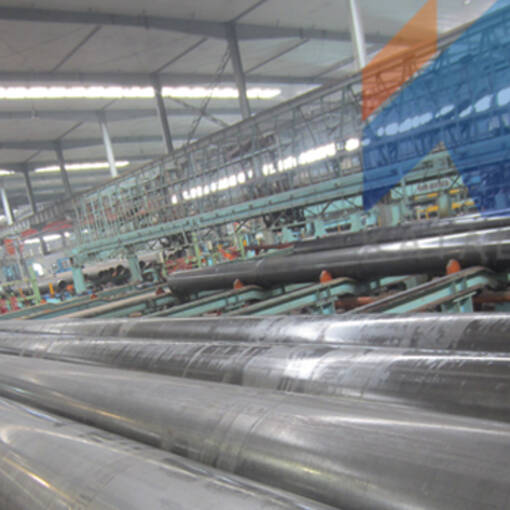

Seamless 16Mo3 alloy steel pipes manufactured to EN 10216-2 standards for high-temperature pressure applications. 16Mo3 is a chromium–molybdenum (Cr–Mo) alloy grade designed for reliable performance in elevated-temperature service such as steam lines, refinery piping and power-plant systems.

Key features and benefits

- Conforms to EN 10216-2 (seamless steel tubes for pressure purposes) and is commonly referenced against ASTM A335 Grade P1 / ASME SA335 P1 for equivalent high-temperature service.

- Chromium–molybdenum alloy for improved creep and scaling resistance at elevated temperatures.

- Supplied in both seamless and welded constructions to meet project specifications.

Typical specifications

- Material grade: 16Mo3 (Cr–Mo alloy)

- Relative/alternative grades referenced: P195GH, P235GH, P265GH, 16Mo3, 13CrMo4-5, 10CrMo9-10, 25CrMo4, X10CrMoVNb9-1

- Outside diameter range: 1/2 in to 24 in

- Wall thickness: from Sch 5S up to Sch XXS (available in common pipe schedules)

- Heat treatment: normalization typically performed between 890 °C and 950 °C with air cooling (as required by project/standard)

Applications

- High-temperature steam piping

- Oil refinery and petrochemical process lines

- Power generation (boilers, superheaters, reheaters)

- Any high-pressure, elevated-temperature service requiring Cr–Mo alloy properties

Supply options and services (typical for industrial buyers)

- Cut-to-length or standard mill lengths

- Seamless or welded pipe supply depending on specification and availability

- Heat treatment and mechanical testing per EN 10216-2 and purchaser requirements

- Mill test certificates (material traceability), non-destructive testing and third-party inspection available on request

- Protective packaging for sea/land shipment

Ordering considerations

Specify the applicable standard (EN 10216-2 or ASTM/ASME equivalent), required diameter and wall thickness (schedule), heat treatment, end finish (beveled, plain, threaded), and any testing or certification needs. Lead times depend on size, quantity and whether seamless or welded construction is specified.

Product Details

Harmonized commodity

Brand:

BBN Steel

Country of origin:

China

Industrial sector:

Unit type:

Metric Ton